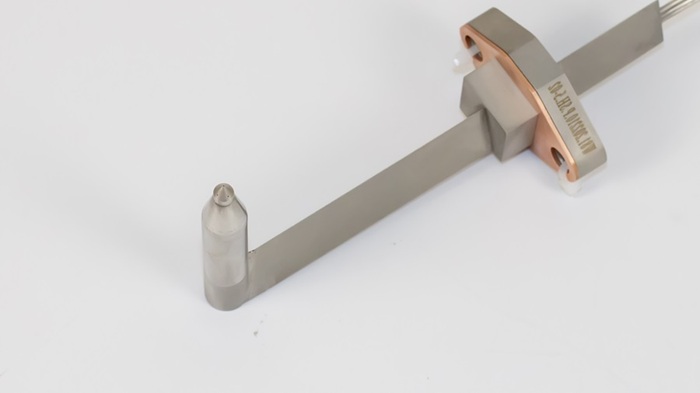

The five-Hole Probe has five manometric holes in two vertical planes, and the intersection of the deflection and pitching surfaces of the two planes passes through the central hole. By measuring the pressure values indicated by the five holes, the airflow velocity and direction at the measured position can be calculated according to the pressure values. It has a compact structure and can measure the complex flow field at multiple points, so it is suitable for the complex air flow inside the compressor.

1. Measurement of flow field parameters

five-Hole Probe can accurately measure parameters such as speed, pressure and direction of the flow field inside the compressor. Compressor impeller, diffuser and other key components, the air flow often presents complex three-dimensional flow characteristics. The five-Hole Probe is able to drill down into these areas to obtain detailed velocity distribution and pressure change data. For example, by measuring the airflow velocity at different positions, the airflow uniformity inside the compressor can be analyzed, and whether there are bad flow phenomena such as airflow separation and vortex can be judged, which provides a basis for the structural optimization of the compressor.

2. Performance evaluation

The performance index of compressor, such as efficiency, pressure ratio and so on, is closely related to the characteristics of internal flow field. Using the flow field data measured by five-Hole Probe, the actual working efficiency and pressure ratio of the compressor can be calculated. Through the analysis of the measured data under different working conditions, we can comprehensively evaluate the performance changes of the compressor, find out the performance bottleneck, and then take targeted improvement measures to improve the overall performance of the compressor.

3. Calibration and verification

In the process of compressor design and development, numerical simulation is a common method. However, numerical simulation results need to be validated by experimental measurements. The experimental data obtained from the five-Hole Probe measurement can be used as an important basis for verifying the numerical simulation results. By comparing the experimental data with the numerical simulation results, the accuracy of the numerical model can be evaluated, the model can be calibrated and improved, and the reliability of the numerical simulation can be improved.

4. Advantages and challenges of five-Hole Probe application

five-Hole Probe has the advantages of relatively simple operation and high measurement accuracy in compressor testing. However, its application also faces some challenges. For example, in the interior of high-speed and high-temperature compressors, the measurement accuracy of the probe may be affected, and special calibration and protection are required. In addition, the installation and arrangement of probes also need to consider the interference problem of the flow field.

five-Hole Probe plays an important role in compressor testing, providing key data support for compressor performance evaluation and optimization. With the continuous advancement of technology, the application of five-Hole Probe will be more extensive and in-depth, pushing compressor technology to a higher level.