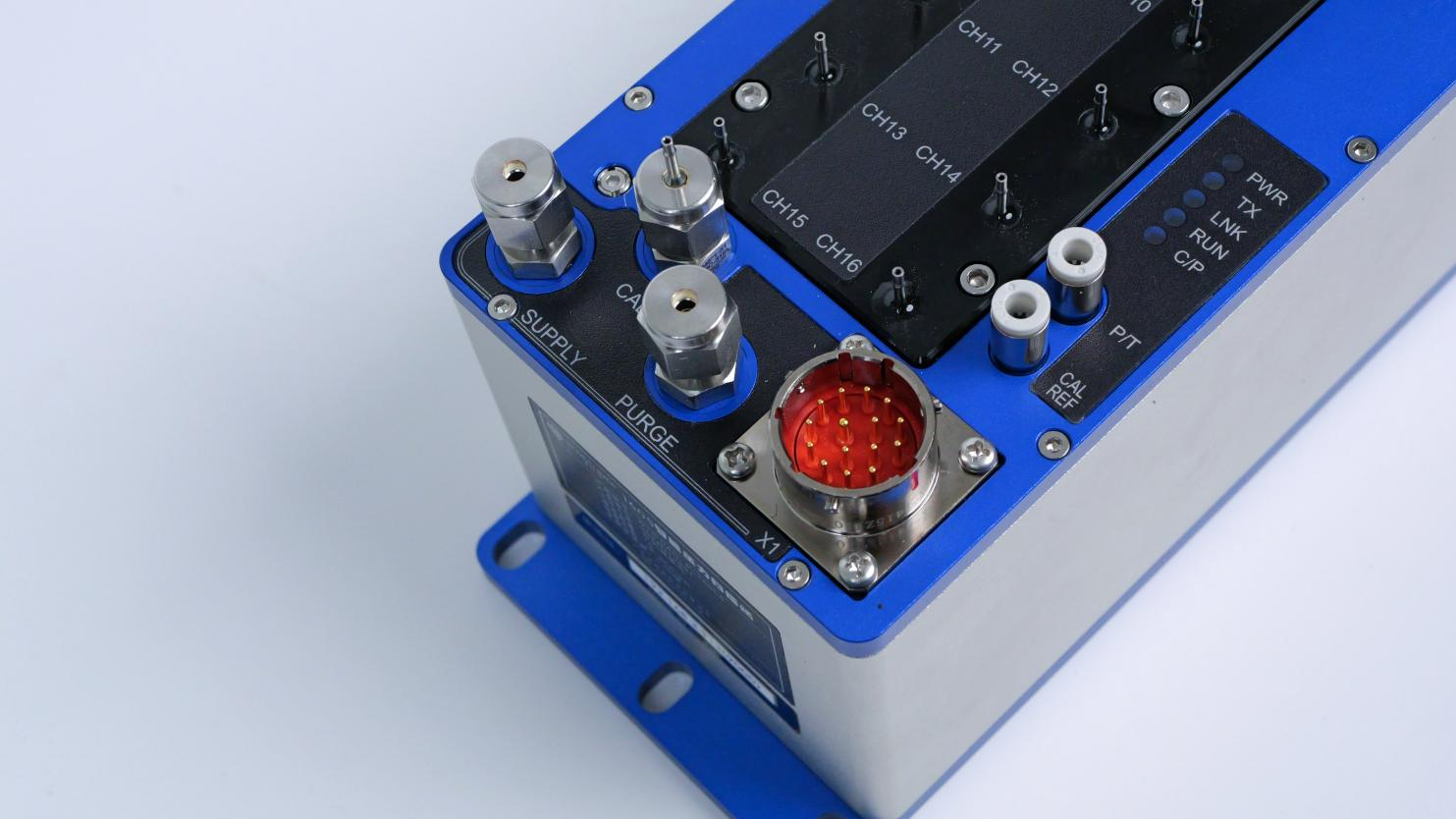

The introduction of the purging function precisely provides an effective solution to this problem. The purging process effectively removes impurities that may accumulate in the valve body and pipelines by injecting clean gas or liquid into the valve regularly or continuously, preventing them from causing damage to key components such as the valve core and valve seat, and ensuring that the Ethernet Intelligent Pressure Scanners operates flexibly and responds quickly. Maintain the best working condition.

Continuous blowing can also reduce the residence time of corrosive media inside the valve, lower the erosion of the valve material by chemical reactions, prevent valve failure caused by material fatigue and wear from the source, and thereby significantly improve the durability and service life of Ethernet Intelligent Pressure Scannerss.

The importance of the purging function to the Ethernet Intelligent Pressure Scanners is self-evident. It not only ensures the normal operation of the valve and reduces the failure rate, but also greatly enhances the economy and reliability of the equipment, providing strong support for achieving safe, efficient and stable industrial production. Therefore, during the use and maintenance of the Ethernet Intelligent Pressure Scanners, the role of the purging function should be fully utilized and emphasized in order to achieve the goal of prolonging its service life.