A large number of independent distributed pressure sensors are usually used to collect data directly. Although this can guarantee the number of measurement points, it brings many problems. First of all, due to the complex structure of the engine and the dense distribution of flow channel measurement points, the number of sensors increases accordingly, resulting in the need to arrange a large number of cables and interfaces, which puts tremendous pressure on the limited airborne space of the flight test platform. Secondly, during the flight, the external atmospheric conditions are complex, and the pressure measuring pipeline is very easy to inhale water droplets. Once it enters high altitude and low temperature, the water droplets condense into ice, which not only blocks the pipeline, but also causes distortion or even complete loss of the airflow pressure signal, seriously affecting the safety of data and tests.

In response to the above problems, some researchers have proposed to replace the distributed sensor solution with the Ethernet Intelligent Pressure Scanners system. Ethernet pressure scanners centrally collects pressure signals from multiple measurement points through multi-channel switching, and converts and outputs by a set of high-precision sensors, thereby increasing the number of sensors required and related wiring. By arranging the location and interface of Ethernet pressure scanners reasonably, the system can flexibly adapt to the limited airborne installation space, and the integration and reliability of the system are improved.

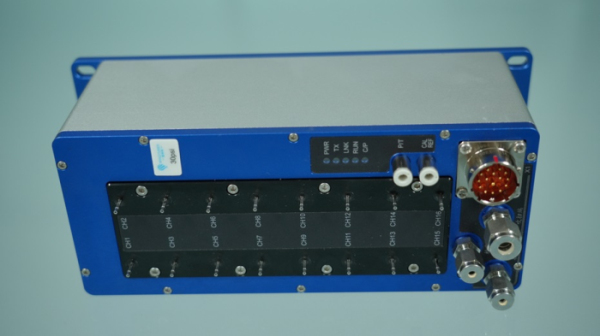

For example, Windtuner Ethernet Intelligent Pressure Scanners, as a representative device of the new generation of Ethernet Intelligent Pressure Scanners series, has become a solution for aerodynamic pressure testing in current flight tests with its highly integrated design and excellent measurement performance. This type of Ethernet Intelligent Pressure Scanners adopts advanced MEMS sensing technology and high-precision analog-to-digital conversion module. It has the characteristics of multi-channel, high speed, and low drift, and can operate stably under harsh conditions such as complex vibration and high and low temperature alternation.

Windtuner Ethernet Intelligent Pressure Scanners is small and compact, and it supports multiple inputs. This centralized measurement not only effectively reduces the wiring complexity and weight burden brought by a large number of independent sensors in the solution, but also significantly improves the overall reliability of the system. and maintenance convenience. At the same time, its communication interface supports various digital protocols such as Ethernet, which is convenient for efficient data interaction with flight control systems or ground monitoring platforms.

The optimization scheme has been applied in the flight test of a certain type of engine. The test results show that the measurement accuracy is not lower than that of the multi-sensor scheme after adopting the Ethernet pressure scanners system, and the system weight and space occupation are significantly improved. Ethernet pressure scanners have fewer sensors and require multiple devices to be used together. After optimization, for example, Windtuner Ethernet Intelligent Pressure Scanners puts 16-channel sensors together, which reduces the number of devices deployed in the test by about 60% and the wiring length by about 50%. The integration of airborne equipment has been greatly improved. In the cold flight test, there was no ice blockage or pressure signal loss in the pipeline after blowback and heating treatment, and the pressure data was continuous and stable, which verified the disturbance immunity and reliability of the system under extreme working conditions.

Based on the aerodynamic pressure test method of Ethernet pressure scanners, researchers have effectively solved the contradictions of large number of sensors, complex layout and limited space in flight test through modular design and function integration. At the same time, combined with high-performance control, the adaptability of the system to harsh flight is enhanced, and the reliability and safety of measurement data are improved. This method is not only suitable for engine flight tests, but also can be popularized and applied to other aircraft test platforms that require high airflow parameters, such as hypersonic vehicles, unmanned aerial vehicles, etc., and has broad scientific research and application prospects.