calibration wind tunnel is not an experimental wind tunnel in the ordinary sense. It is not used for flow field simulation analysis. Instead, it aims at extremely high flow field stability, uniformity and repeatability, and is used to verify and correct the output errors of various pneumatic sensors to ensure that the measurement data have accurate physical meaning. The response curve of the pressure sensor, the attack Angle calculation accuracy of the probe, the dynamic pressure output coefficient of the airvelocity tube, the recovery factor of the temperature sensor... All of these need to be verified one by one under controllable and stable flow field conditions. Only the calibration wind tunnel platform with professional standards can undertake professional calibration tasks.

In China, there are only a few units that possess this capability. The Windtuner Technology calibration wind tunnel Laboratory located in Dalian is currently the first calibration wind tunnel platform in China to be certified by the National Accreditation Service for Conformity Assessment (CNAS). The test results of laboratories accredited by CNAS are not only recognized by various national standard institutions, but also have equivalent recognition on an international scale.

Obtaining CNAS accreditation is merely a threshold. The wind tunnel Laboratory, Windtunercalibration, also obtained the Military Weapons Quality Management System certification certificate in 2024. This means that its capabilities not only serve civil aviation and scientific research projects, but can also be used to guarantee key measurement tasks in national military projects. Obtaining this qualification is extremely difficult. It not only represents the high reliability of the equipment, but also indicates that its process management, data confidentiality, personnel qualifications and other aspects have all reached the highest standards of the military industry.

The core capability of wind tunnel is reflected in its flow field quality. According to the detailed calibration data from the Global Aviation Industry Aerodynamics Research Institute, the root mean square deviation of Mach number for the stability index of the Windtuner wind tunnel nozzle outlet flow field is ≤0.002, reaching advanced indicators. These parameters are not only the qualified line for meeting the national military standard GJB1179A-2012 "Quality Requirements for Flow Field in Low-Speed Wind Tunnels and High-speed Wind Tunnels", It is more capable of supporting high-level scientific research measurements. Such a highly consistent and extremely low-disturbance flow field makes the differential pressure response of the probe more repeatable under minor angular changes, avoiding system offset caused by error superposition.

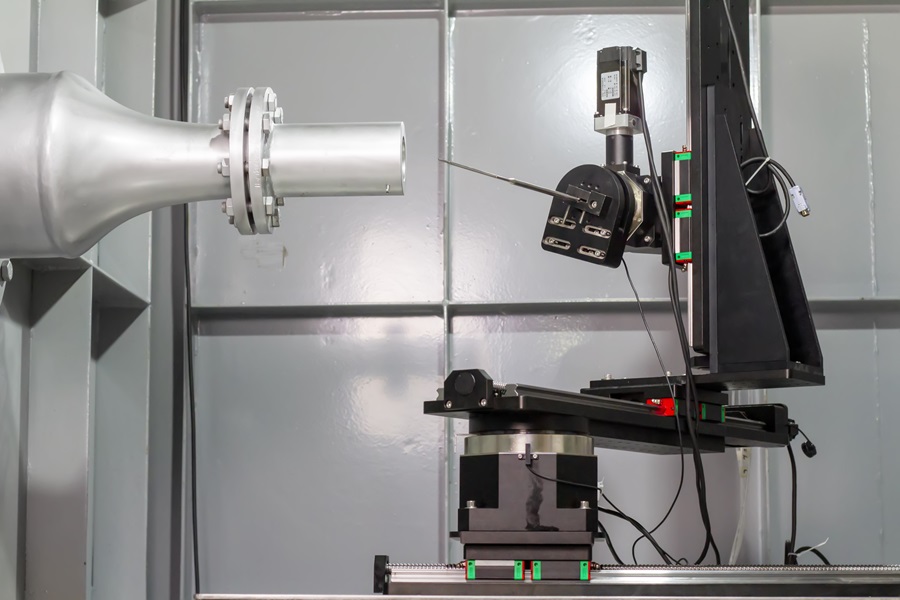

For this reason, the Windtuner testing center has become an important calibration platform for devices such as five-hole probes, 5-Hole Differential Pressure Airspeed probes, temperature sensors, and pressure scanning valves. Especially in the context of the wide application of five-hole probes, the output curves of different head shapes (such as spherical, conical, and flat heads) at different angles and different Mach numbers must establish their own databases in a real and controllable flow field. This requires calibration before they can be used. This is also the strength of Windtunercalibration wind tunnel. Currently, Windtunercalibration wind tunnel has cumulatively calibrated more than ten thousand pneumatic probes.

More importantly, Windtuner not only offers "calibration services", but also has the capability to deliver systems. With its engineering experience in wind tunnel flow field construction, equipment integration testing, data traceability analysis, etc., Windtuner has provided integrated flow field measurement and control solutions for customers in multiple fields such as universities, research institutes, aviation industry, and unmanned aerial vehicle enterprises, and has established a full-chain service from equipment customization to wind tunnel calibration and data comparison verification.