WINDTUNER can customize and produce a full range of pneumatic probes according to customer test requirements,including probe material,shape,hole number,hole diameter,probe size,length of support rod,shape and size of mounting seat,strength and blocking ratio calculation,etc.In order to meet the requirements of more complex and demanding test conditions and accuracy requirements,WINDTUNER combined with the German professional team,Print pneumatic probes with the world's leading micrometer-scale metal additive manufacturing technology.

Apply the world-leading micron-level metal additive manufacturing (3D printing) technology

Smaller aperture:Through additive manufacturing technology, the blocking rate is smaller and the aerodynamic performance is better.

More accurate positioning:The probe is printed in one go, allowing for a more complex probe structure.

Higher strength:Optimize the geometric mutation positions to reduce the problem of stress concentration.

Integrated services are tailor-made

Demand clarification:The customer communicates and confirms the relevant parameters of the flow field.

Probe design:Design the probe scheme according to the test requirements.

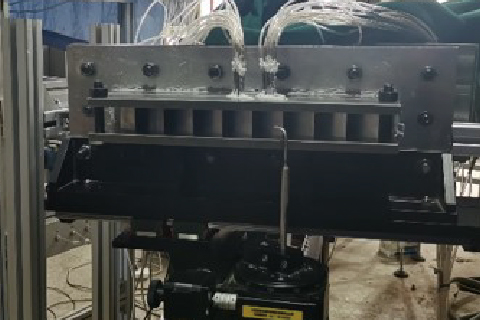

Probe processing:Determine the manufacturing process and carry out material preparation and processing.

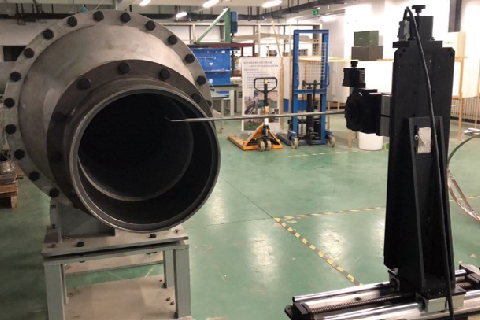

Probe calibration:Calibrate the probe using a professional calibration wind tunnel.