Client Name: Dalian University of Technology

Client Needs:

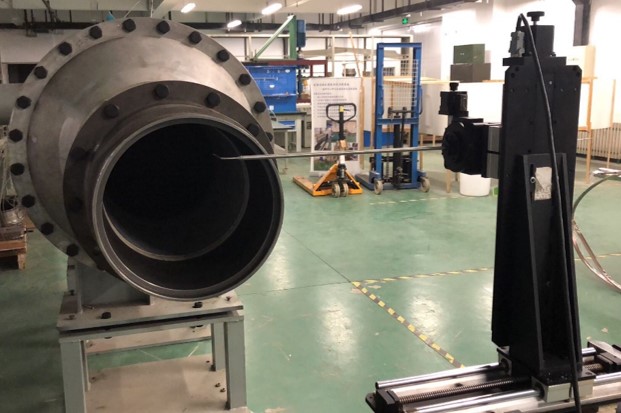

Dalian University of Technology requires a systematic test of the flow field uniformity at the wind tunnel exit section for an experiment. The specific requirements are as follows:1. Pressure and Flow Velocity Measurement: Accurately collect the static pressure, dynamic pressure distribution, and fluid flow velocity at the exit section.

2. Flow Direction Analysis: Capture the fluid flow direction within the three-dimensional flow field.

3. Automated and Efficient Data Acquisition: Achieve parameter measurement at the required points in the flow field space through a high-precision displacement mechanism.

Products Used:

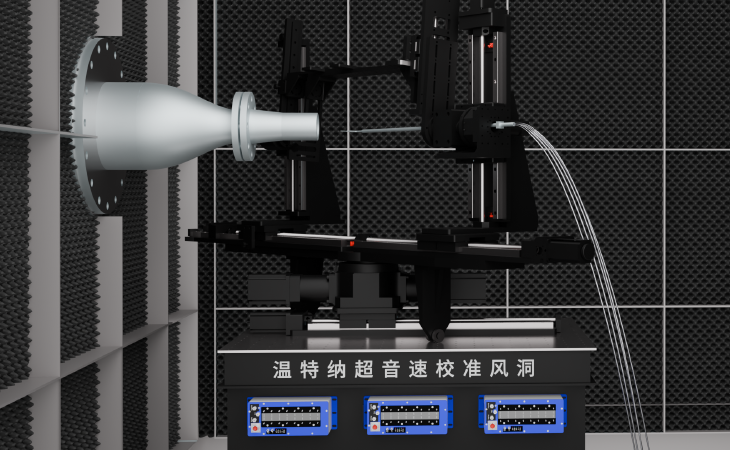

1. Five-Hole Probe:Adopts the non-opposed measurement method to support synchronous acquisition of three-dimensional velocity and pressure fields.Integrates a five-hole probe interpolation algorithm to enhance measurement accuracy.2. Intelligent Pressure Scan Valve:A 16-channel high-precision pressure acquisition system with an accuracy of Class 0.05.Supports real-time synchronous data recording.

3. Electric Displacement Mechanism + Motion Controller:Comprises both a rotary stage and a translation stage, paired with a motion controller to form a high-precision fully automatic positioning and scanning system for three-dimensional flow fields.

Case Details:

1. Test Plan Design1.1 Flow Field Simulation and Measurement: Simulate actual flow field parameters, arrange measurement points at the wind tunnel exit section, and drive the five-hole probe to measure parameters at the target points along a preset path using the electric displacement mechanism and motion controller.

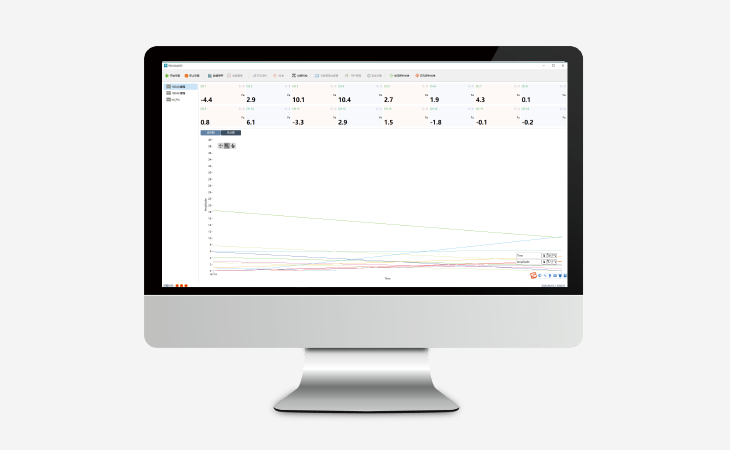

1.2 Data Synchronization Acquisition: The pressure scan valve collects pressure values measured by the five-hole probe, which are analyzed and calculated through the measurement and control software to obtain the parameters required for the experiment.

2. Key Technical Applications

2.1 Five-Hole Probe Interpolation Algorithm: Utilizes Wintner’s proprietary patented technology to improve the measurement accuracy of the probe in the flow field and reduce the error rate.

2.2 Automated Control: The motion controller enables multi-axis linkage, and when paired with the WindLabX measurement and control software, shortens the single full-section scanning time.

Experimental Results:

1. Data Accuracy Met Standards:The flow velocity measurement error was ≤ 0.05%, and all indicators such as angle coverage range met the test requirements.2.Efficiency Enhancement:The automated scanning of the electric displacement mechanism improved test efficiency, enabling rapid measurement and acquisition of data.