Client: Xi'an Jiaotong University

Client Requirements:

Xi'an Jiaotong University requires fully automated inter-stage flow field testing in the blade grid wind tunnel. Specific requirements include:Fully Automated 3D Flow Field Acquisition:Implement automated systems to perform point-by-point scanning measurements of three-dimensional velocity fields and pressure distributions within blade grid channels.

5-Hole Differential Pressure Airspeed Probe Calibration:Conduct calibration under 0.2/0.4/0.6/0.8Ma (Mach number) conditions to ensure measurement accuracy and performance meet experimental specifications.

Products Applied

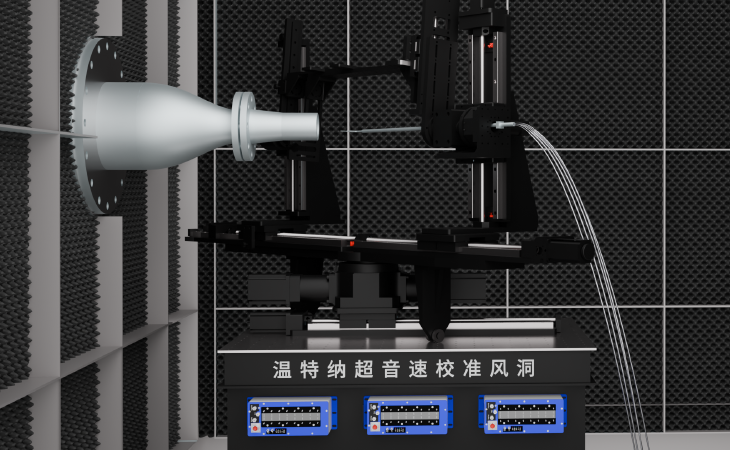

5-Hole Differential Pressure Airspeed Probe (Windtuner):Independently designed and manufactured by Windtuner.Minimum aperture <0.02 mm with superior aerodynamic performance

Ethernet Intelligent Pressure Scanners:16-channel synchronous acquisition system.Pressure accuracy: 0.05% FS.Real-time pressure parameter acquisition for flow field analysis.

Electric Displacement Mechanism:Precision positioning system.Repeat positioning accuracy <0.003°.Integrated translation/rotation stages enabling 360° flow field measurement.

Motion Controller:Multi-axis coordinated control.On-the-fly adjustment of pulse output count and drive speed.

Case Details

Experimental Background

Xi'an Jiaotong University required high-precision testing that traditional manual measurements could not meet, necessitating a fully automated solution.

Probe Calibration & Flow Field Characterization

5-Hole Differential Pressure Airspeed Probe Calibration:Performed dynamic pressure calibration at 0.2/0.4/0.6/0.8Ma conditions in the calibration wind tunnel;Followed Windtuner's standard calibration process;Post-calibration measurement accuracy met all experimental requirements.

Blade Grid Flow Field Measurement:Drove the 5-Hole Differential Pressure Airspeed Probe through 3D movements via Electric Displacement Mechanism;Completed data collection from hundreds of measurement points in blade grid channels.Integrated Automated Measurement and Control System

Motion Path Planning:Planned probe measurement paths based on blade grid geometric models using Motion Controller and Electric Displacement Mechanism;Achieved full coverage of all flow field measurement points.

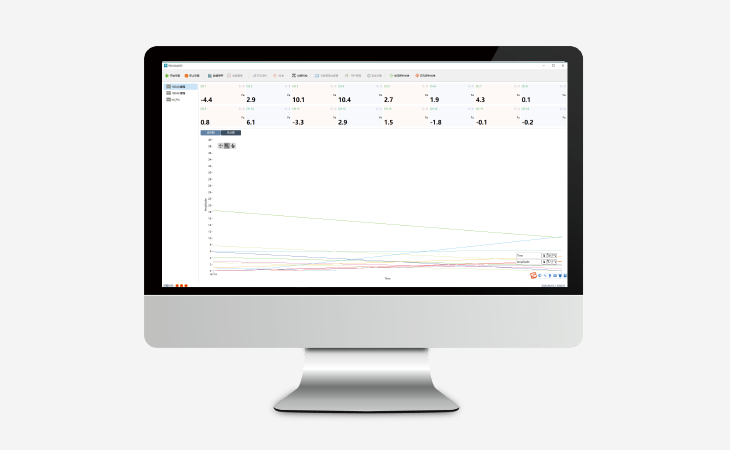

Multi-device Synchronization Control:Established distributed data acquisition system through WindLabX Measurement and Control Software;Implemented parallel networking control of multiple devices.Experimental Results

Breakthrough in Data Accuracy:Velocity field measurement error: 0.15% FS (vs. required 0.2%);Pressure resolution: 5 Pa (surpassing 8 Pa specification);Probe angular coverage: ±85° (exceeded experimental standards);Successfully completed probe calibration and data acquisition per ASME PTC 19.1

Automation Process:Established an automated acquisition system integrating;Windtuner probes Ethernet Intelligent Pressure Scanners (20 kHz sampling),Motion controller (0.003° positioning accuracy),Achieved 68% efficiency improvement compared to manual operations.