The complexity and accessibility of aerodynamic models have reached new heights with 3D printing. 3D printing can greatly reduce the cost and time needed to manufacture critical components, capable of creating advanced designs like micro perforated structured wings and efficiency-optimized turbine blades. In aerospace, motor sports, and aerial research, 3D printing also expands the geometric limitations of traditional manufacturing, showing us a possibility of efficient, lightweight aerodynamic designs.

Multiple milestone achievements in 3D-printed aerodynamics emerged in 2025: Germany’s SE²A Cluster of Excellence for Sustainable Aviation at Technical University of Braunschweig developed laminar wings using 3D-printed suction panels, whose laminar boundary layer reduces 90% air friction than the turbulent boundary layer. Aerospace engine giant GE Aviation leveraged 3D printing to produce their engine components, and has begun full-scale production of the its GE9X engines, which feature over 300 3D printed parts.

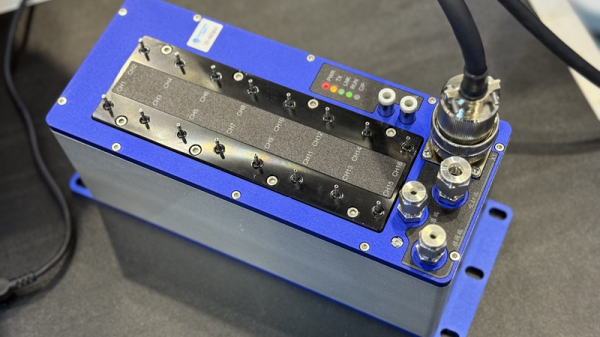

The refined 3D-printed models serve to overcome greater airfield pressure challenges. We rely on the accurate measurement of pressure scanners to know how its fluid pressure works. Based on the data collected from pressure measurement, we validate which 3D-printed models . As a professional producer of pressure scanners, Windtuner is ready and qualified to embrace the 3D-printing era of aerodynamic R&D. Focused on pressure measurement technology since 2017, Windtuner has centered on providing solutions for flowfield measurement and control. Its flagship products, the Windtuner pressure scanner and its five-hole probe are suitable additions to 3D-printed aerodynamic R&D, matching its urgent needs. Windtuner pressure scanners are fully qualified by CNAS and CE standards. Every scanner is carefully calibrated upon production. Its 16 channels contain one-click pressure calibration functions to ensure consistent equipment accuracy.

Components 3D-printed are much more delicate than those traditionally manufactured, therefore miniature deviation could cause laminar airflow layers to become turbulent layers, reducing its design advantage. The irregular surfaces of 3D-printed components require especially accurate and flexible pressure scanners to properly measure. This calls for accurate and aerodynamic measurement tools: probes custom and flexible enough to capture pressure distribution differences on complex surfaces, and pressure scanners reliable and efficient enough to complete data collection while enduring extreme temperature, strong turbulence and other harsh testing environments. Windtuner’s pressure scanner is capable of functioning under temperatures of -30~60℃ with total thermal error of no more than ±0.001%FS/℃. The pressure scanners support one-click automatic purging which continuously keep the equipment in best condition even in complex environments.

The aerodynamic advantages of 3D-printed components often depend on micro-structures, and the effectiveness of these structures must be verified through pressure distribution data. Critical 3D-printed components such as turbine blades and aircraft wings require not only aerodynamic efficiency but also the ability to withstand structural loads from airflow pressure. Pressure scanners safeguard the quality of these components by preventing structural risks and performance instability. Windtuner pressure scanners can monitor fluid flow fields of the models with a pressure accuracy better than 0.05%FS. Windtuner also provides a variety of multi-hole pressure probes, providing tailored products to measure differential data such as atmospheric pressure and atmospheric temperature.

As 3D-printing technology continues to deepen its contribution in the aerodynamics field, Windtuner is the trustworthy choice for a customized solution of pressure measurement for complex structures.