After long-term use, the sensor may face the challenges of abnormal signal output and decreased measurement accuracy. Abnormal signal output is mainly manifested as unstable signal output by the sensor or large deviation from the actual pressure value, which may be due to wear and aging of internal components of the sensor, loose, bad wiring or electromagnetic interference, as well as unstable power supply voltage or poor power supply and other factors.

To deal with these problems, the sensor should be checked regularly and the damaged parts should be replaced in time, all connecting wires should be secured and shielded wire interference should be considered, and a regulated power supply or UPS (uninterruptible power supply) should be used to ensure power supply.

The absence of an output signal from pressure scanners sensors is also a common failure. This is usually caused by faulty power supplies, damaged sensors, or faulty signal transmission lines. When troubleshooting such faults, we first need to check whether the power supply is normal to ensure that the voltage and current meet the requirements of the sensor. At the same time, it is also necessary to check whether the signal transmission line is connected normally, and whether there is an open or short circuit.

Inaccurate sensor measurements are also a common problem in daily use. This may be due to sensor aging, calibration failure, or external interference. In this case, we need to recalibrate the sensor to ensure that its measurement accuracy meets the requirements.

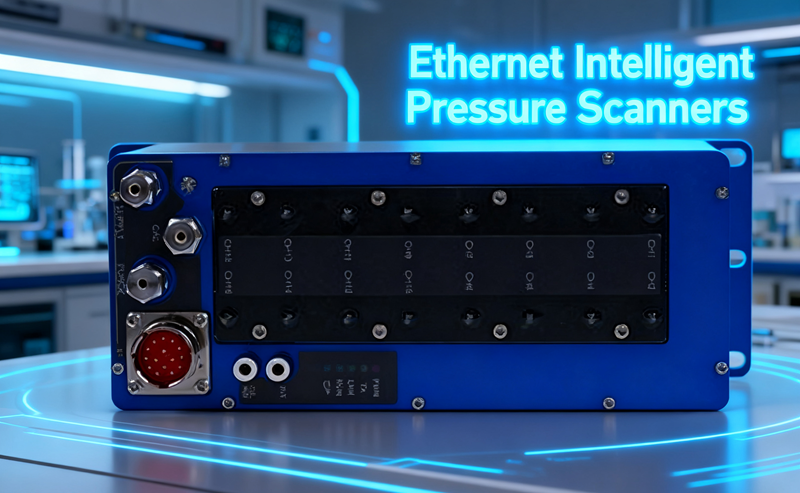

Zero drift is also one of the common faults of sensors. This may be due to temperature changes or changes in performance due to use. To solve this problem, WindtunerEthernet Intelligent Pressure Scanners will zero-calibrate the sensor and take temperature compensation measures to account for the impact of temperature on the sensor.

Finally, the slow response speed of the sensor is also a concern. This may be due to some of its own limitations as well as problems with the signal processing circuitry. For this case, we can consider replacing a more responsive sensor model, or checking and repairing the signal processing circuit to improve the sensor's responsiveness.

Although the sensors in pressure scanners may have a variety of failures, through regular maintenance, reasonable selection and correct use methods, these problems can be effectively prevented and the stable operation of the system can be ensured. However, purchased products such as WindtunerEthernet Intelligent Pressure Scanners will largely avoid these situations. Even if a problem occurs, the staff of Windtuner Technology will respond in a timely manner to help everyone avoid worries.