The Optimal Specification to Solve Your Problem

Many buyers assume that a seven-hole probe is always a better choice than a five-hole probe;or they may think otherwise and assume that a 14-hole probe is just a ripoff version of a seven-hole probe. Neither of these are the case. The pressure holes on a probe head are always reasonably located in order to operate the way it is meant to. Considering necessity and cost factors, more holes does not guarantee more accurate results or higher efficiency. When a certain probe design is capable of solving an issue, purely increasing numbers do not bring better results. Competent brands like Windtuner ensure that every product delivered can fully complete its designated duty, rendering more holes little more than budget waste. So always quality over quantity and other unnecessary specifications.

The type of probe needed really depends on the problem at hand. For example, a three-hole probe is often enough to work well in a two dimension flow field, because its three aligned holes make it possible to calculate the angle and direction of any incoming pressure, as long as it stays within a single plane. But for pressure data acquisition in 3D environments, researchers require at least five-hole probes to properly indicate the angle and direction parameters. The more turbulent, complex the testing environment is, the more holes are needed for the probe head to remain accurate. Increased number of holes allow the tool to monitor more complex flow field planes, as well as measure air movement from larger entry angles. Common upgraded designs include seven-hole and even thirteen-hole probes. Also, manufacturers creatively use different shapes to deal with different situations.

How Different Shaped Probes Meet Complicated Requirements

We find many shapes of probes besides the classic Pitot tube design. They are meant to improve probe performance, accuracy and stability under different flow fields. Every probe design widely produced and applied today is the fruit of countless aerodynamic research and testing.

The omniprobe is a probe with a ball-shaped probe head, covering a very large angle(reaching 150° and beyond), making it perfect for measuring flow fields that are less stable and require surveillance on many angles, such as around vehicle wheels.

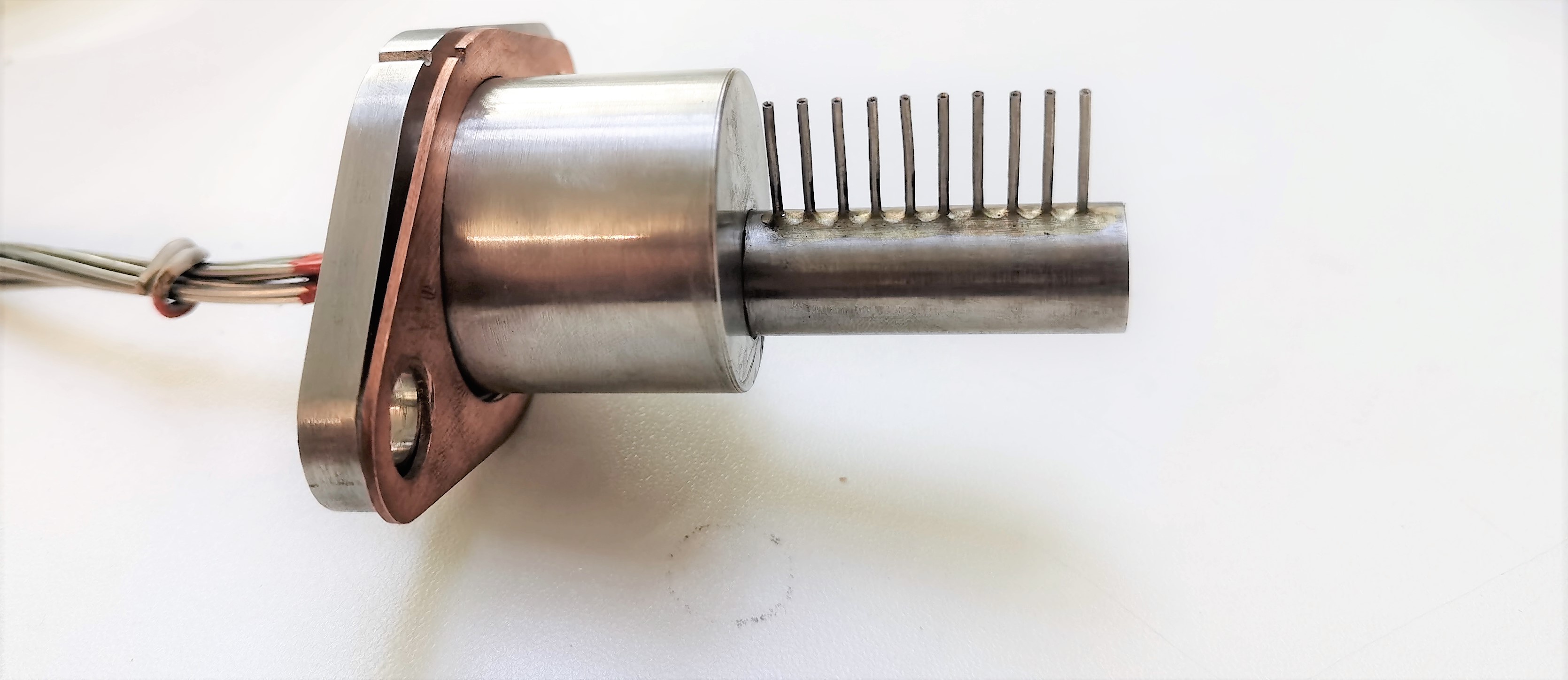

The rake-shaped probe has multiple tips aligned along a metal neck, allowing it to measure different points of the flow field simultaneously. Each tip is usually a standard multi-hole probe, ensuring its accuracy and stable performance. It is designed to save time for researchers in projects where they, if only with one probe, would need to reinstall the probe and repeat the same test multiple times.

Expertise and Knowledge of Probe Variations

We at Windtuner have ample experience in adjusting and manufacturing probes of all shapes and hole numbers. Windtuner specializes in pneumatic probe production, especially heeding to customer requirements, including the material, strength, shape and structure. The length of the probe body and size of the top can also be adjusted for different usages. In addition, Windtuner possesses the proficiency to provide multi-holed probes with desired size and amount of holes according to the user's actual applications.

Windtuner houses a professional aerodynamic research team. Their expertise is proven through the tens of thousands of differentiated probes Windtuner has produced. Every probe is tested by our certified wind tunnel laboratory, and product prototypes endure 10000+ hours of durability examination before these prototypes are sent to mass production.

There are always situations that need new solutions or specifications to best solve, and we provide full support to your urgent needs. When it comes to customization, Windtuner presents various solutions for probe design, covering function, shape, and capability. Through collaboration with German professional teams, Windtuner strives to design probes specialized to fulfill the requirements of even the most complex and harsh experiment environments.

Overall, our opinion is that any probe is a carefully and scientifically manufactured solution for at least one specific situation, where it excels in performance and cost-efficiency. Windtuner provides solutions to every phase of aerodynamic R&D. Our common mission with our client is to work together and find the best solution-Leave the rest to us and we promise to offer you the most suitable, competent and high-quality probe to meet your needs.