Understand How a Pressure Scanner Works in Two Minutes

As a professional pressure scanner manufacturer, Windtuner used over a decade to refine our products through multiple generations of R&D. These upgrades include far more than performance improvements. From external design to internal architecture, Windtuner pressure scanners reflect our focus on engineering rigor, operational reliability, and industrial professionalism.Industrial Design Built for Real Testing

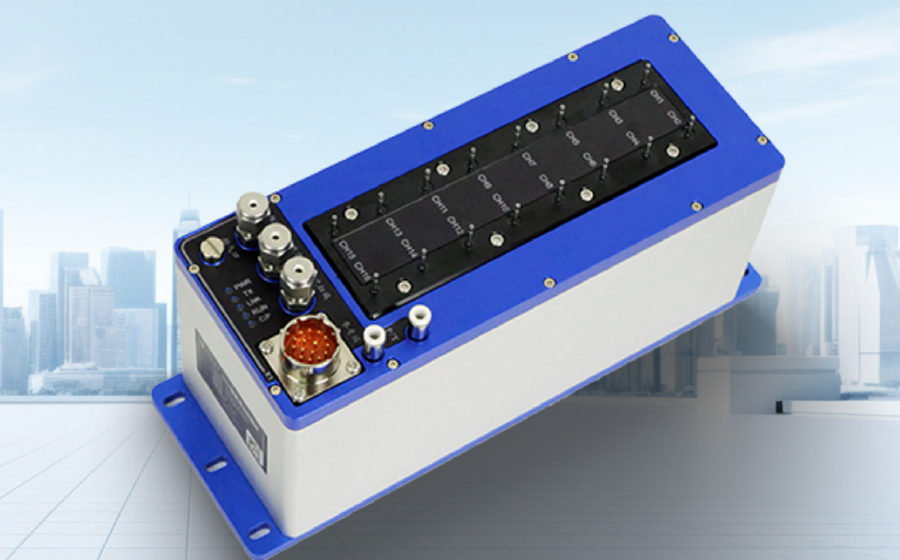

The exterior of a Windtuner pressure scanner is a balance between practical engineering and modern industrial aesthetics. A robust metal enclosure forms the structural backbone of the device, providing strong protection against vibration, temperature fluctuation, and long-term operational stress. The signature blue housing, combined with precision-machined metallic edges, communicates both high performance and mechanical reliability—qualities essential for demanding environments such as wind tunnel laboratories, engine test benches, and turbomachinery facilities.

The Windtuner Ehternet Intelligent Pressure Scanner

On the top panel, Windtuner integrates multiple ports and control components designed for streamlined installation and intuitive operation. Each interface is clearly labeled, reducing setup time and minimizing the risk of connection errors during complex test configurations. Standard configurations include built-in atmospheric pressure and ambient temperature sensors, allowing the pressure scanner to continuously track environmental conditions—an essential requirement for maintaining high measurement accuracy.

Several dedicated functional interfaces are distributed across the housing. The CAL REF port connects external reference standards for calibration, supporting long-term accuracy stability. The CAL port enables internal system calibration and verification, while the PURGE interface supports pneumatic cleaning to prevent contamination during extended operation. Power stability is handled through the SUPPLY port, while the VENT outlet releases excess pressure to avoid pressure-induced measurement deviations.

An aviation-grade X1 connector delivers secure electrical connections under harsh conditions, and the Ethernet interface provides network access for remote operation, monitoring, and data transfer. Equipment identification information, including model number and production batch, is permanently marked on the nameplate to support traceability and lifecycle management. A top-mounted display presents real-time system status and measurement data, giving engineers immediate visibility during testing.

Every interface is positioned with maintenance, accessibility, and system integration in mind, allowing Windtuner pressure scanners to fit seamlessly into both laboratory and field test environments.

How a Windtuner Pressure Scanner Works

At its core, a Windtuner pressure scanner performs high-accuracy pressure acquisition and processing for aerodynamic and flow field testing. The operating principle is based on differential pressure measurement, using multiple pressure channels to compute key flow parameters such as pressure distribution, flow velocity, and flow direction.Pressure data enters the system through multiple input ports connected to the test object or probe system. These inputs typically include total pressure, static pressure, and additional pressure points distributed across the flow field. High-accuracy internal sensor modules capture pressure values simultaneously across all channels, ensuring consistent temporal alignment.

Once acquired, the internal electronics calculate pressure differentials between channels. These differentials form the basis for determining flow characteristics, including velocity components and spatial flow behavior. Thanks to high-resolution A/D conversion and fast internal processing, Windtuner pressure scanners complete this analysis within extremely short time intervals, supporting both steady-state and transient measurements.

The processed data is handled by the scanner’s internal acquisition and control system, then transmitted to external computers or test platforms through Ethernet communication. Engineers can monitor measurements in real time, store data for post-processing, or integrate the scanner into automated test systems using measurement and control software.

A Windtuner Pressure Scanner in Calibration

To maintain long-term performance, Windtuner pressure scanners support automatic calibration and system self-checking. The integrated calibration reference interfaces allow routine verification against external standards, while internal calibration routines detect and correct drift before it affects test results. This approach supports stable operation throughout extended test campaigns.

Environmental adaptability is another key design focus. Built-in atmospheric pressure and temperature sensors continuously compensate for changes in ambient conditions. Even when temperature or pressure fluctuates significantly, the pressure scanner maintains consistent accuracy. Venting and purge interfaces further protect the pneumatic system from contamination, ensuring stable performance during prolonged operation.

A Reliable Foundation for Advanced Flow Field Measurement

By combining robust industrial design with a well-engineered measurement principle, Windtuner pressure scanners have become indispensable tools in flow field testing. Their accurate data acquisition, stable operation, and flexible system integration make them well suited for aerospace research, engine testing, wind tunnel experiments, and a wide range of industrial applications.As flow measurement technology continues to evolve, Windtuner continues to expand the capabilities of its pressure scanners through advanced manufacturing, intelligent electronics, and rigorous calibration standards. The next generation of testing and control technologies will support engineers worldwide obtain accurate aerodynamic data.