First, the method of use

Step 1 prepare

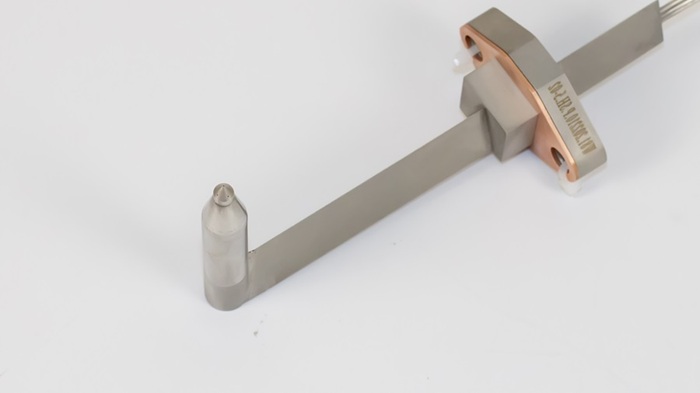

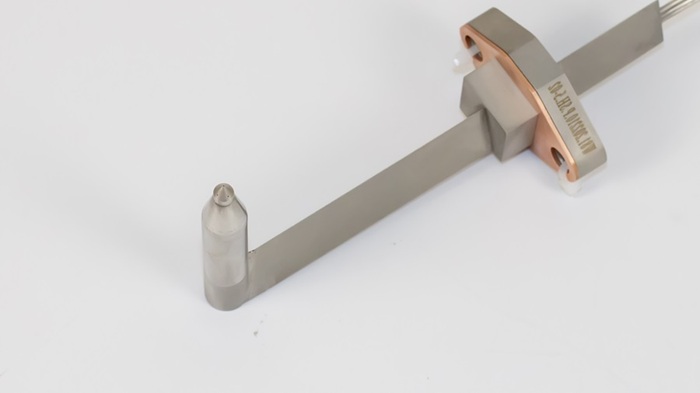

Firstly, check the calibration certificate of the pneumatic probe to ensure that the pneumatic probe is within the effective calibration period; Secondly, check the design working conditions of the pneumatic probe and the working conditions to be tested to ensure that the pneumatic probe is used within the working conditions; Finally, confirm the size of the interface or joint of the probe and acquisition equipment, and prepare a sufficient number and length of pipelines to ensure that the probe and acquisition equipment can be connected correctly.

Step 2 check

Check whether the appearance of the pneumatic probe, the measuring point, the pressure-inducing pipe and its interface, the temperature measuring lead and its connector are complete, check whether the pneumatic probe leaks or is blocked by air source equipment such as air pump, and connect it to the temperature acquisition equipment to check the continuity of the temperature measuring point.

Step 3 install

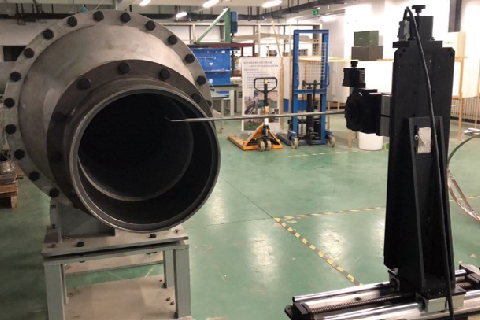

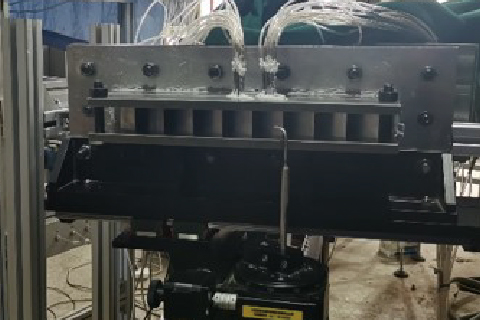

According to the test requirements, install the pneumatic probe in the corresponding test section, and adjust the installation angle of the pneumatic probe so that the probe measuring point or the head sensing hole is facing the incoming flow direction or preset angle. If the probe has a mounting seat, check whether there is a matching sealing gasket to ensure the sealing performance.

Step 4 connect

Connect the probe pressure pipe to the pressure acquisition equipment by pipeline, and ensure that there is no air leakage;

Connecting a probe temperature measuring lead to a temperature acquisition device; Tie the pressure lead and the temperature measuring lead, and do a good job of protection.

Connecting a probe temperature measuring lead to a temperature acquisition device; Tie the pressure lead and the temperature measuring lead, and do a good job of protection.

Second, matters needing attention

1. Before using the pressure probe, check whether there is any foreign matter at the measuring point. It is necessary to use an air pump and other air sources to pump air from the pressure-inducing pipe joint to blow away foreign matters such as accumulated dust, accumulated water or grease, and ensure that the ventilation and air tightness are intact.

2. During the installation of pneumatic probe, pay attention to protect the pneumatic probe and its measuring point from bumping. Pay attention to the bolt torque at the clamping position or mounting seat to prevent the probe from moving during the test due to loose clamping, which will affect the test safety; Prevent the probe from being deformed due to too tight clamping, resulting in inaccurate measurement angle, which may seriously cause the probe to hit the test piece, resulting in damage of the probe and the test piece.

3. During the installation and use of the mobile measurement type pneumatic probe, attention should be paid to the movement track and stroke of the probe, and whether there will be contact interference during the movement of the probe or the test piece, otherwise it will bump or damage the pneumatic probe and the test piece.

4. When the pneumatic probe is installed and wired, the pressure-inducing tube and the temperature measuring lead shall be effectively protected, so as to avoid the damage caused by knotting and excessive bending caused by disordered wiring, which will affect the measurement. The bending angle of pressure lead and temperature measuring lead should not be too large, and excessive bending will lead to the failure of ventilation, air tightness, electrical performance and insulation performance.

5. The medium measured by pneumatic probe should be clean, dry, corrosion-free and dust-free, so as to avoid damaging the probe or affecting the measurement accuracy.

6. When using the pneumatic probe, avoid out-of-range use and ensure that it is used within the range of using temperature, using pressure and required strength.

7. If the pneumatic probe needs to be installed on the test bench for a long time, attention should be paid to the protection of the pressure tube and the temperature measuring lead to avoid bending or breaking due to the influence of gravity for a long time.

2. During the installation of pneumatic probe, pay attention to protect the pneumatic probe and its measuring point from bumping. Pay attention to the bolt torque at the clamping position or mounting seat to prevent the probe from moving during the test due to loose clamping, which will affect the test safety; Prevent the probe from being deformed due to too tight clamping, resulting in inaccurate measurement angle, which may seriously cause the probe to hit the test piece, resulting in damage of the probe and the test piece.

3. During the installation and use of the mobile measurement type pneumatic probe, attention should be paid to the movement track and stroke of the probe, and whether there will be contact interference during the movement of the probe or the test piece, otherwise it will bump or damage the pneumatic probe and the test piece.

4. When the pneumatic probe is installed and wired, the pressure-inducing tube and the temperature measuring lead shall be effectively protected, so as to avoid the damage caused by knotting and excessive bending caused by disordered wiring, which will affect the measurement. The bending angle of pressure lead and temperature measuring lead should not be too large, and excessive bending will lead to the failure of ventilation, air tightness, electrical performance and insulation performance.

5. The medium measured by pneumatic probe should be clean, dry, corrosion-free and dust-free, so as to avoid damaging the probe or affecting the measurement accuracy.

6. When using the pneumatic probe, avoid out-of-range use and ensure that it is used within the range of using temperature, using pressure and required strength.

7. If the pneumatic probe needs to be installed on the test bench for a long time, attention should be paid to the protection of the pressure tube and the temperature measuring lead to avoid bending or breaking due to the influence of gravity for a long time.

Third, maintenance

Step 1 clean

The pneumatic probe should be cleaned in time after use, and can be wiped with a dry, clean and lint-free cleaning cloth. After each test, the pressure probe pressure pipes and pressure holes should be cleaned by air source equipment such as air pump, and it is suggested that the back blowing time should be (5-10)min, so as to avoid dust accumulation, water accumulation, grease and other foreign bodies from affecting the next measurement accuracy. The temperature probe should clean the position of the measuring point.

Step 2 store

After the pneumatic probe is used, rubber cap or special protective sleeve should be used to cover the hole and interface of the measuring point to prevent dust or other foreign matter from entering the pressure measuring hole and the interface of the pressure pipe; Generally, the orifice of the measuring point is sharp, so it is necessary to avoid bumping, and do a good job in bundling the pressure lead pipe and the temperature lead wire harness. Pneumatic probes should be placed in special packaging boxes; if there is no special packaging box for probes, the probes should be placed horizontally on shelves or equipment racks, and the storage environment should be kept dry and free from dust. It is forbidden to hang or lean against the wall, otherwise the probe will be deformed and the measurement accuracy will be affected.

Step 3 calibrate

Long-term use of pneumatic probes is recommended to be calibrated at least once a year. If the pneumatic probe has not been used for more than half a year, it is recommended to send it to a probe calibration unit approved by China National Accreditation Committee for Conformity Assessment (CNAS) for re-calibration.

Fourth, troubleshooting

1. Abnormal pressure indication

If the pressure measurement of the pressure probe is low or high, first check whether the interface connected with the acquisition equipment and the connected pipeline are blocked or leaked, and then check whether the probe is blocked or leaked.

1. Blockage detection method:

Back-blow the pressure probe pressure pipes and pressure holes with air pump and other air supply equipment. If there is no air flow or extremely small air flow at the corresponding measuring point or hole position, it can be confirmed that the pressure probe is blocked. You can use air pump and other air supply equipment to back-blow the pressure probe pressure pipe joint for a long time. If the blockage situation does not improve, please contact the manufacturer in time for treatment.

2.Leak detection method:

Put the pressure probe in a clean water tank, and use air pump and other air source equipment to blow back from the interface of the probe pressure pipe, and observe the position and frequency of bubbles (wipe and blow dry the water on the probe pipeline and surface after completion). If bubbles appear except the position of the measuring point hole, it can be confirmed that the pressure probe has air leakage at this position, so please contact the manufacturer in time for treatment.

1. Blockage detection method:

Back-blow the pressure probe pressure pipes and pressure holes with air pump and other air supply equipment. If there is no air flow or extremely small air flow at the corresponding measuring point or hole position, it can be confirmed that the pressure probe is blocked. You can use air pump and other air supply equipment to back-blow the pressure probe pressure pipe joint for a long time. If the blockage situation does not improve, please contact the manufacturer in time for treatment.

2.Leak detection method:

Put the pressure probe in a clean water tank, and use air pump and other air source equipment to blow back from the interface of the probe pressure pipe, and observe the position and frequency of bubbles (wipe and blow dry the water on the probe pipeline and surface after completion). If bubbles appear except the position of the measuring point hole, it can be confirmed that the pressure probe has air leakage at this position, so please contact the manufacturer in time for treatment.

2. Abnormal temperature indication

If the temperature probe has inaccurate measurement or no indication, it can first check whether the measuring point is equipped with dirt or oil stains and other attachments that affect the measurement, and if so, it can be simply cleaned; Secondly, check the probe temperature measuring lead and its connector to see if there is any damage, fracture, etc. If so, please contact the manufacturer for treatment; Finally, check whether there are other heat sources or cold sources near the temperature probe. If there are, relevant measures should be taken to avoid its influence.

3. Physical damage

If the pneumatic probe encounters impact during use, resulting in physical changes such as bending at the probe measuring point, scratches on the measuring point position, deformation of the measuring point position, please contact the manufacturer for repair and recalibration to avoid affecting the measurement accuracy.4. Other faults

In case of other problems that can't be solved, please contact the manufacturer in time for treatment and repair. It is recommended to re-order those damaged beyond repair (such as serious blockage, bending deformation, broken probe, and failure to weld and repair the pressure lead or temperature measuring lead again).Through the above use and maintenance methods, we can ensure that the pneumatic probe can still maintain high precision measurement in complex environment and prolong its service life. If you have other questions or need further help, please feel free to contact technical support.