Reinventing Probe Manufacturing with 3D Printing

Aerodynamic probes are conventionally fabricated through precision turning, micro-drilling, and welding – processes prone to structural limitations, accumulated error, and long production cycles. 3D printing overcomes these challenges by directly building intricate metal geometries from digital models through laser or electron-beam melting. A wide range of printable materials – including tungsten, titanium, cobalt-chromium, nickel-based alloys, and stainless steel – perform reliably under extreme conditions such as high temperature, high pressure, or corrosive environments. This allows one-piece forming of multi-hole channels, delivering outstanding repeatability and precision.

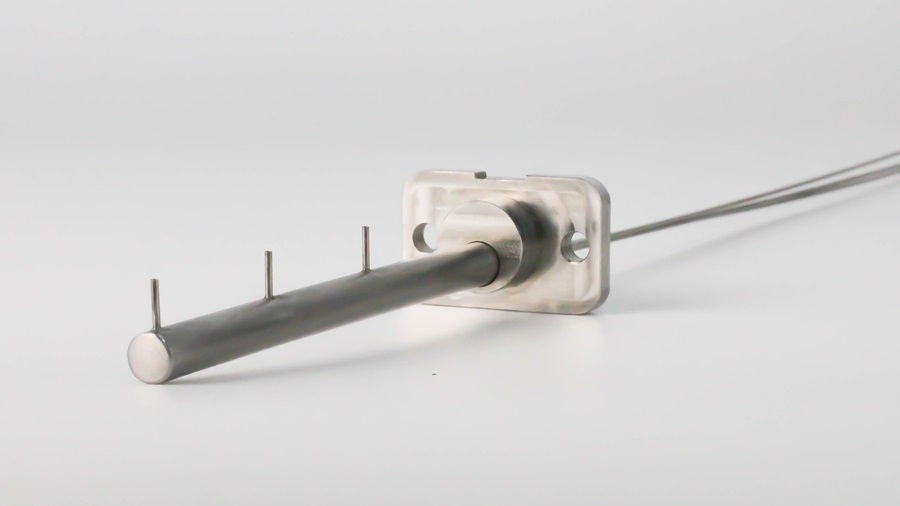

Three-Hole Probe: Compact and Responsive

Designed to measure static and total pressure as well as flow angles, the three-hole probe benefits greatly from 3D printing. The process ensures higher dimensional accuracy and symmetry, minimizing drilling-induced deviation. The probe’s aerodynamic contour can also be optimized to reduce flow interference and improve response time.

For applications such as UAV testing or small-scale wind tunnel experiments where space is limited, 3D printing achieves a balance between miniaturization and high sensitivity, delivering fast and accurate measurements in lightweight configurations.

Five-Hole Probe: The Core of Precision Flow Measurement

The five-hole probe is the standard choice for three-dimensional velocity measurements in wind tunnel and turbomachinery testing. With 3D printing, Windtuner’s five-hole probes avoid undergoing welding and assembly, steps that potentially harm geometric integrity, airtightness, and superior angular accuracy.

Internal flow paths can be optimized to minimize energy loss, while topology-optimized designs achieve the ideal balance between structural strength and lightweight performance. Using high-temperature alloys such as cobalt-chromium or nickel-based materials, 3D-printed probes maintain stability in extreme environments like turbine test rigs or high-speed wind tunnels.

Rapid prototyping and short production cycles further give engineers the flexibility to validate designs quickly and transition to small-batch production without costly tooling. This combination of accuracy, adaptability, and reliability makes the 3D-printed five-hole probe the benchmark choice for high-precision flow measurement.

Seven-Hole Probe: Comprehensive 3D Flow Capture

For highly turbulent or rotational flow regions, the seven-hole probe offers complete three-dimensional velocity and pressure data. Its complex geometry and submillimeter hole spacing pose significant challenges for traditional machining, but 3D printing enables precise angular control and perfect alignment between ports.

Through integrated digital modeling, engineers can incorporate signal channels, support structures, or even temperature-compensation units directly into the probe body, reducing assembly error and system noise.

This capability makes 3D-printed seven-hole probes indispensable for high-end research applications such as advanced wind tunnel experiments and engine performance testing, where spatial resolution and temporal response are critical.

Unified Advantages of 3D-Printed Multi-Hole Probes

Across all types of advanced measurement devices, 3D printing brings substantial benefits:Higher precision, stronger structural consistency, customizable geometry, fast delivery, and exceptional material flexibility for our probes. By eliminating manufacturing constraints and enhancing aerodynamic quality, 3D-printed probes deliver performance levels unattainable through conventional methods.

Windtuner’s micron-level additive manufacturing technology has paved the way for intelligent, lightweight, and highly customized aerodynamic probe production. We’ve collectively sold thousands of three-hole, five-hole, seven-hole, or even thirteen-hole and other shapes of probes. With continued improvements in printing accuracy and material science, the next generation of probes will play an even greater role in advancing aerodynamic research and industrial testing worldwide.