In the field of flow measurement and control, this is especially true. For engineers and researchers, a high-performance pressure scanner serves as a dependable foundation for trustworthy data, efficient workflows, and controllable risks. Resolving to devices that do not match said needs risk turning the entire experiment into a cycle of recalibration, wasted time, and lost resources.

Reliability Determines Research Efficiency

Scientific testing is a battle against time, variables, and uncertainty. In high-precision domains such as wind tunnel testing, engine evaluation, and fluid mechanics measurement, equipment stability directly shape the experiment’s pace.

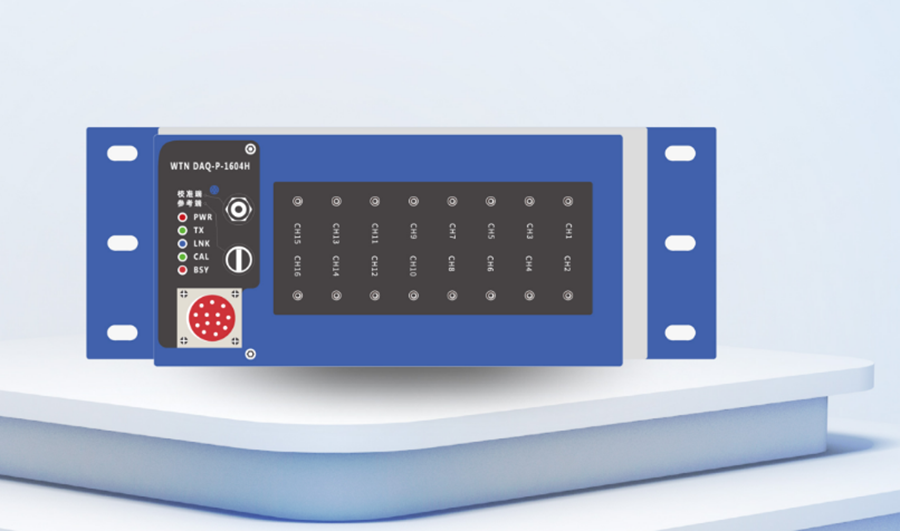

Within a flow-field measurement system, the pressure scanner is the heart of data acquisition. It must capture dynamic pressure changes across multiple channels in real time, delivering high bandwidth and high accuracy simultaneously. Any signal drift, latency, or channel instability compromises results—and may force the entire test to restart.

Reliable instruments minimize repeat tests, shorten experiment duration, and reduce maintenance cycles. That efficiency allows researchers to focus on analysis and theoretical breakthroughs instead of troubleshooting.

Windtuner recognizes this core principle. Each Windtuner pressure scanner undergoes rigorous vibration, temperature, and pressure-cycle tests during design and production, ensuring stability in challenging environments such as engine test benches, wind tunnels, and high-temperature labs.

Engineering for Endurance—Quality as the Foundation of Efficiency

Research environments are rarely gentle. Engine test stands bring extreme vibration, temperature, and pressure; wind tunnels introduce airflow pulsation and temperature gradients; outdoor tests confront unpredictable weather shifts. All of these challenge an instrument’s endurance.

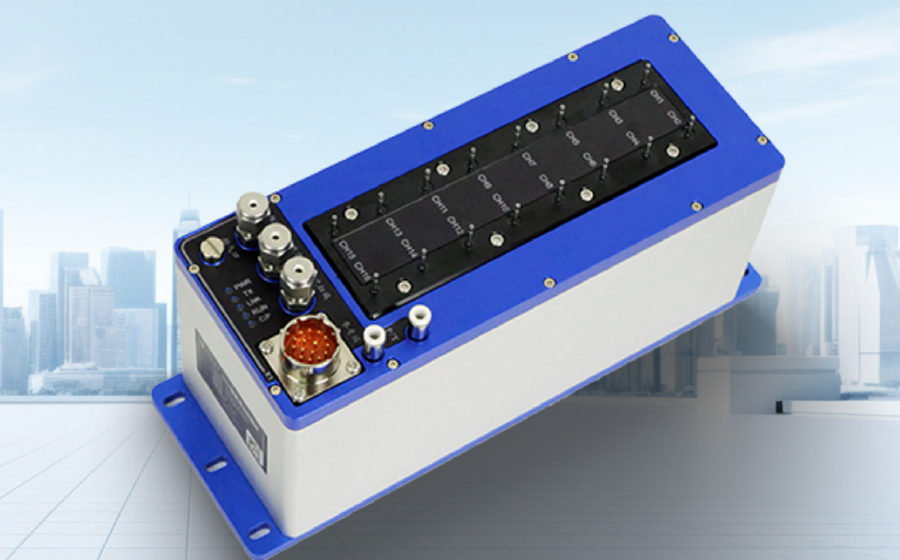

Windtuner designs every pressure scanner with an engineering mindset—focusing on reliability, continuity, and consistency. Downtime or signal drift can waste valuable hours or even invalidate entire datasets. To prevent that, Windtuner employs anti-vibration and impact-resistant architecture optimized for stable operation under severe mechanical stress. With a wide temperature adaptability from -30°C to 60°C, and overpressure protection and anti-blockage pneumatic design, Windtuner’s pressure scanner maintains accuracy across variable conditions, with reduced risk of sensor damage and maintenance costs.

By enforcing these essential functions, Windtuner pressure scanners sustain consistent output across complex experimental conditions, ensuring each project stays on schedule.

Smarter Integration, Faster Progress

Efficiency improves with the integration of data transmission. Windtuner integrates intelligent calibration, automated zeroing, and open software architecture to accelerate every research stage. The built-in intelligent calibration system allows internal zeroing, full-scale calibration, and user-defined multi-point calibration—eliminating the need for disassembly and reducing operational risks.

Its software ecosystem supports complete workflows, from data acquisition and real-time display to post-processing and visualization. With open protocols and flexible interfaces, researchers can rapidly configure custom test systems without additional programming.

Multi-channel synchronization enables simultaneous pressure sampling across all ports, offering real-time visualization of aerodynamic characteristics and faster analysis cycles.

Reliablity as a Time-Saver

Long-duration experiments depend on instruments that endure continuous stress. Each Windtuner pressure scanner passes intensive lifecycle testing—including high-low temperature cycles, vibration endurance, and pressure fatigue verification—to maximize mean time between failures.

This invisible reliability translates into real-world productivity—every avoided maintenance interruption brings teams closer to their milestones.

Long-Term Value: Quality is the True Cost Saver

Initial cost is only part of the equation. Over time, high-quality instruments deliver the greatest value. While lower-end devices may appear economical at first, their frequent recalibration, data drift, and potential breakdowns accumulate hidden costs—delaying projects and consuming budgets.

Windtuner emphasizes long-term stability and measurement consistency. Each verified pressure scanner maintains precision over years of operation, ensuring credible data accumulation and repeatable results. Windtuner puts full effort into offering competitive or superior performance pressure scanners comparable to international models such as PSI 9216 and DSA 3217, but at a significantly lower price point, proving affordability and excellence can coexist.

Scientific innovation relies on both human ingenuity and dependable tools. Choosing the right instrument is a strategic investment in efficiency, accuracy, and research continuity. As Windtuner believes: "Better instruments empower better research." In an era that demands precision and speed, Windtuner pressure scanners stand as not just laboratory equipment, but reliable research partners that accelerate discovery and innovation.