Experienced buyers understand that purchase price is just the tip of the iceberg. Hidden costs in operation, maintenance, and downtime often determine the real value. From procurement to long-term service, Windtuner helps clients see the complete picture.

Purchase Price Is Just the Beginning – Hidden Costs Define the Experience

In aerodynamic laboratories or gas turbine test systems, the pressure scanner serves as the data acquisition core. Any malfunction or drift in accuracy can lead to experimental interruptions or distorted results. Beyond the initial purchase, users often face additional hidden expenses:

Calibration costs: Regular calibration is essential for long-term stability. Imported equipment typically must be shipped back for factory calibration – a slow, costly process that brings many uncertainties and risks.

Maintenance and spare parts: Replacement parts for imported models are expensive and often take months to arrive.

System integration and training: Closed communication protocols and poor compatibility mean additional engineering hours and software adjustments.

Downtime and stalling: For research institutions, a single delayed experiment can disrupt an entire project schedule at worst.

Such hidden costs can exceed 20%–50% of the product’s price. In other words, buying it doesn’t cover it for the whole way.

The Windtuner Ethernet Intelligent Pressure Scanner

The Emergence of a Substitution – Windtuner Makes Measurement More Economical and Efficient

As China makes steady progress in measurement and control technology, Windtuner pressure scanners are helping clients reduce total ownership costs through systematic innovation.

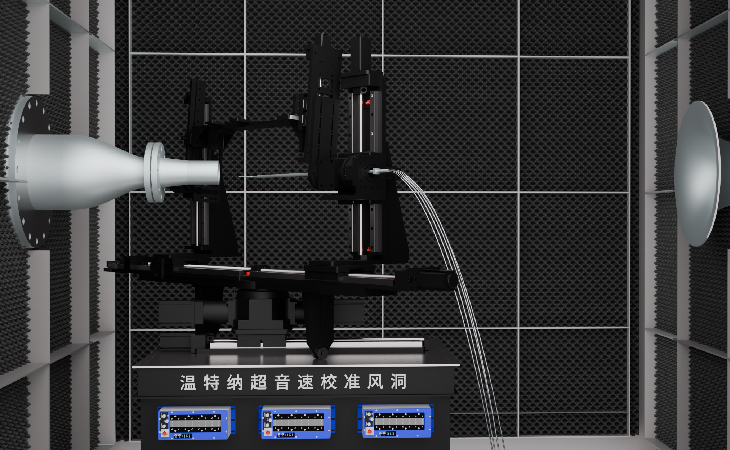

Windtuner's Self Developed Supersonic Wind Tunnel

Low-cost, high-efficiency calibration: Supported by an self-developed wind tunnel pressure laboratory accredited by CNAS, Windtuner offers fast and professional calibration services for its own scanners as well as other brands. Clients benefit from shorter turnaround times and assured accuracy.

Open interface and flexible compatibility: Windtuner pressure scanners adopt open communication protocols, easily integrating with mainstream measurement systems. This reduces system integration time, ensures plug-and-play deployment, and significantly lowers setup costs.

Modular and serviceable design: Modular construction allows for quick replacement of critical components without factory return, minimizing downtime and financial loss.

Full lifecycle technical service: From selection, installation, and calibration, to maintenance and data analysis software, Windtuner provides one-stop solutions that merge hardware and software for optimized efficiency and long-term reliability.

Scientific Management and Localized Support – Extending Equipment Lifespan

Choosing a cost-effective device only makes up part of the equation. Proper management further lowers long-term costs. Windtuner encourages clients to establish data-based health archives for each pressure scanner, recording calibration cycles and temperature drift conditions for predictive maintenance rather than resorting to reactive repair. Combined with Windtuner’s intelligent self-checking feature, this approach extends product life and reduces unexpected downtime.

As we have discussed above, the lowest price rarely equals the lowest cost when it comes to research and intelligent manufacturing products. True competitiveness lies in achieving cost optimization throughout the entire lifecycle while maintaining precision and reliability. With a fully self-developed technology framework, responsive local service, and continuously evolving intelligent control capabilities, Windtuner encourages clients to buy smart and use smarter. From procurement to operation, Windtuner stands by every client – you not only own it, you master it.