Precise Response to Various Applications

Windtuner's pressure scanners are widely used in numerous scientific research and engineering fields like wind tunnel testing, cascade experiments, and engine inlet tests. In these highly complex and precise practices, measurement equipment must possess exceptional stability and adaptability. To meet the needs of different experimental scenarios, Windtuner's pressure scanners offer various customization options, including range selection, functional module configuration, communication modules, pneumatic interfaces, and communication cables. This ensures every customer can select the most suitable product for their experimental requirements.

In wind tunnel tests, Windtuner's pressure scanners can accurately measure the pressure distribution on aircraft surfaces, helping engineers and researchers obtain accurate aerodynamic data.

Perfect Integration of High Accuracy and Modular Design

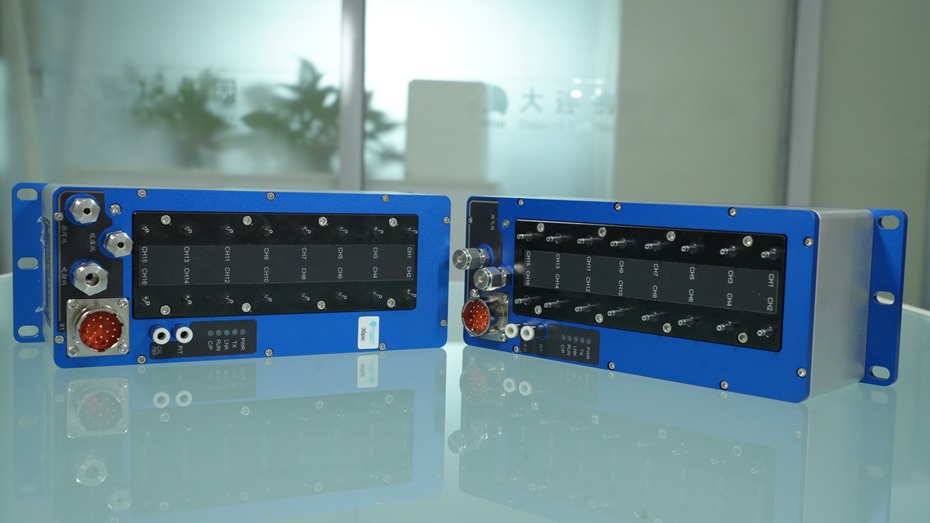

The Ethernet Intelligent Pressure Scanner is Windtuner's core product, and it fully demonstrates Windtuner's expertise in customized design. Employing advanced microprocessor technology, the scanner uses sensor data stored in EEPROM circuits to calibrate zero point, range, linearity, and thermal errors. This not only effectively eliminates errors caused by temperature variations but also ensures accuracy in various environments through the microprocessor's intelligent control.

The modular design of the pressure scanner allows each functional module to operate independently or combined, flexibly meeting diverse needs. During the process of design, need for flexibility is fully considered, offering high configuration flexibility through a split modular design.

Customized Range Selection to Meet Diverse Experimental Environment Needs

Selecting appropriate ranges matters most when high accuracy and robust reliability are required. The Windtuner Ethernet Intelligent Pressure Scanner offers 16 range segments from -2.5 kPa to 1000 psi, catering to various experimental needs from low to high pressure. This allows range adjustments to be made according to actual requirement, optimizing the result of the experiment.

For certain tests that need much more sensitive data acquisition, traditional ranges might not meet accuracy requirements. Windtuner pressure scanners address this need by providing customization for measurement range. Through range adjustment, users can select smaller differential pressure measurement ranges to more accurate and stable performance under high differential pressure conditions.

In engine inlet experiments, pressure in the test environment can fluctuate dramatically, placing extremely high demands on the pressure scanner's accuracy and stability. Windtuner pressure scanners maintain high accuracy of ±0.05% FS under extreme pressure variations. Through intelligent temperature compensation algorithms, Windtuner scanners ensure that even in extreme environments, measurement errors caused by thermal drift do not occur.

Customizable Frequency and Data Transmission for Efficient Experiment Requirements

Beyond range and accuracy, the data acquisition frequency and transmission speed are vital for pressure scanner performance. The sampling frequency of Windtuner pressure scanners ranges from 0 to 500 Hz and can be adjusted, meeting requirements for high-frequency data acquisition. It is capable of rapidly responding to flow field changes.

Furthermore, Windtuner pressure scanners support adaptive 10/100M Ethernet communication using TCP/IP and UDP/IP protocols, enabling fast data transfer and ensuring real-time data acquisition and accuracy during experiments. Timestamps can be sourced from the internal clock, an NTP clock, or an IEEE 1588-2008 Precision Time Protocol master clock. This design ensures precise synchronized data acquisition when multiple devices work together.

Easy Integration and Software Support

Windtuner designs its products to be simply used and easy to integrate. Windtuner pressure scanners come equipped with PC-based measurement and control software written in LabVIEW. Users can easily integrate them into existing experimental platforms without extra development. This customer-friendly design significantly reduces the complexity for usage, saving time and cost.

Comprehensive after-sales service for your pressure scanner is another major perk in the Windtuner solution. Windtuner's tech support team provides 7*24 service. From product installation, configuration and debugging, to daily technical inquiries, Windtuner offers professional support to see to your every concern.