I. Mechanical Age: From Static Pressure Capture to Dynamic Response Optimization (1920s-1980s)

The core mission of the early pitot tube was to solve the reliable measurement of flight speed. In 1926, the L-shaped single-hole tube invented by French engineer Henri Peto established the basic principle framework by calculating the airspeed through the difference between total pressure and static pressure. However, under transonic conditions, the accuracy of the pitot tube drops sharply due to shock wave interference (error exceeds ± 15%), and attitude parameters such as angle of attack and sideslip angle cannot be obtained. In the 1960s, NASA took the lead in launching the five-hole direction probe, which realized three-dimensional flow field analysis through five pressure holes symmetrically distributed on the hemispheric head, improved the angle of attack measurement accuracy to ± 0.5 °, and constructed the first pressure coefficient and flight parameters mapping database.

Technological breakthroughs during this period focused on:

Structural anti-flutter design: adopts streamlined head (aspect ratio 1.5: 1) and support rod damping structure to suppress pressure fluctuation caused by airflow separation;

Adaptive upgrade: The electric heating anti-icing system (1968 Boeing 707 standard configuration) solves the problem of icing and blockage, ensuring high humidity reliability;

Dynamic calibration system: Based on the wind tunnel test, a shock wave correction model in the full Mach number range is established to reduce the transonic error to ± 3%.

Although the Pitot tube achieves the leap from a single parameter to perception at this stage, it is still limited by the hysteresis effect of mechanical transmission (response time > 100ms) and the nonlinear interference of complex flow field.

II. Electronic Revolution: Multi-Sensor Fusion and Intelligent Compensation (1990-2020s)

The penetration of microelectronics technology has pushed the Pitot tube into the digital age. The Integrated Air Data Module (ADC) launched by Honeywell in 1995 is the first to package pressure sensors, temperature probes, and inertial units in the same shell to realize multi-parameter synchronous output of airspeed, altitude, and temperature. After 2010, MEMS (micro-electromechanical system) technology gave birth to a wave of miniaturization:

Silicon-based piezoresistive sensor: reduce the size of the pressure element to the millimeter level (such as GE's MEMS probe size 3 × 3 × 1 mm ³), increase the bandwidth to 10kHz, and can capture the details of the turbulence spectrum;

Multi-physical field coupling compensation: the embedded temperature-sensitive chip corrects the change of gas density in real time (accuracy ± 0.1%), and the anti-electromagnetic interference characteristics of fiber Bragg grating (FBG) technology expand the applicability of thunderstorm weather;

Dynamic data fusion: The Kalman filter algorithm fuses inertial navigation (INS) and GPS data to suppress body vibration and noise, and the time-average airspeed error is < ± 0. 3 m/s.

Technical bottlenecks during this period focused on reliability at extremes: high temperatures (> 800 °C) lead to failure of silicon-based devices, strong electromagnetic interference (such as fighter radar) causes signal drift, and iterations of materials and packaging technologies.

3. Intelligent Transition: Digital Twin and Quantum Sensing Reconstruction Measurement Paradigm (2020s-2030s)

At present, the airspeed tube is undergoing a paradigm shift from "hardware sensor" to "intelligent perception node", and three major trends are particularly significant:

1. Materials Science and Extreme Adaptation

Ultra-high temperature ceramic matrix composites: silicon carbide fiber reinforced ceramics (SiC/SiC) can withstand 1600 °C and are used in hypersonic vehicles (such as SR-72 in the United States);

Self-repairing coating: bionic microcapsule technology (such as hollow glass beads loaded with healing agent) can automatically repair after scratches, improving the ability to resist sand and dust erosion (life is extended by 3 times);

Flexible electronic integration: Graphene/PVDF composite film probes can fit complex curved surfaces (such as the leading edge of UAV wings) to realize distributed pressure field monitoring.

2. Miniaturization and Array Perception

MEMS array probe: 10 × 10 micro probe matrix deployed on the wing surface, with a spatial resolution of millimeter level (German DLR applied to A350 laminar flow wing optimization);

Lab-on-Probe: Integrate temperature, humidity, and particulate matter concentration sensors (such as the standard configuration of Airbus A220) inside the probe to build a flight holographic database;

Quantum pressure sensing: A quantum probe based on diamond NV color centers (Cambridge laboratory prototype) achieves 0.1 Pa-level ultra-sensitive measurements, breaking through the analytical limit of turbulent microstructures.

3. Digital twins and autonomous evolution

Real-time flow field reconstruction: combine CFD simulation and probe data to generate a three-dimensional pressure cloud image to predict risks such as separated flow and vortex rupture (Boeing 777X has achieved cockpit visual early warning);

AI dynamic calibration: deep learning algorithms (such as convolutional neural networks) independently optimize calibration curves based on historical data to adapt to unsteady flow fields (the calibration period is shortened by 90%);

Autonomous Health Management: Built-in Vibration Spectrum Analysis Module Predicts Probe Cracks, Plugging, and Other Faults (NASA Deployed in the X-59 Silent Supersonic Demonstrator).

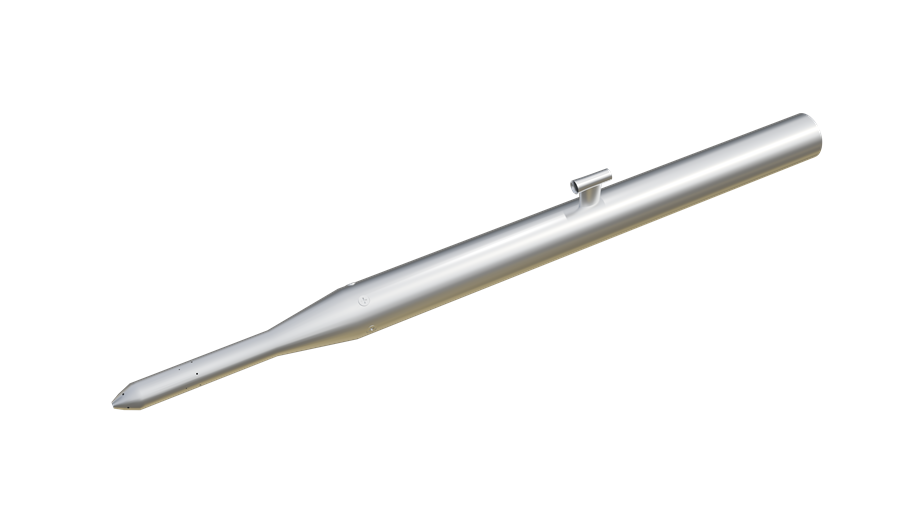

Windtuner has innovatively launched a five-hole differential pressure airspeed tube, which can provide aircraft with flight altitude, speed, angle of attack, sideslip angle, static pressure, dynamic pressure, total atmospheric temperature and static temperature data. In terms of performance, it is stronger than the performance of a single-hole space-velocity tube.

The century-old evolution of the airspeed tube is essentially a concrete process of human cognition of the nature of flow. The future airspeed tube is no longer a cold metal part, but an intelligent life body integrating perception, computing, and communication. It will escort the aircraft test and flight stages with atomic-level accuracy and millisecond-level response.