Early Origins: Military and Demand Driven

The concept of ethernet pressure scanners originated from the early multi-point pressure measurement system, and its original intention was to meet the urgent needs of military and field wind tunnel measurement. In these sophisticated fields, accurate acquisition of multi-point pressure data is crucial for the design and performance evaluation of aircraft, engines and other equipment. The early pressure measurement methods are limited, and the measurement accuracy and efficiency are not satisfactory. The emergence of ethernet pressure scanners has brought new opportunities to solve these problems.

Industrial Application Expansion: Diversified Measurement Requirements

With the gradual development of technology, ethernet pressure scanners began to expand from the military field to the industrial field. In aircraft, engine, wind tunnel and other tests, the requirements for pressure data and quantity are increasing day by day. ethernet pressure scanners are gradually emerging in industrial production by virtue of their advantages in volume, easy installation, system integration and scanning speed. It not only meets the diverse needs from wind tunnel test to high-accuracy pressure test, but also is used in large-scale industrial flow field, turbine test, compressor test and bridge wind engineering, and has become an indispensable tool in industrial measurement.

Technological Innovation: The Leap from Mechanical to Electronic

Before the 1950s, the multi-point pressure measurement in wind tunnel tests and fluid dynamics experiments was mainly based on the liquid pipe method. This method is cumbersome in operation, large in measurement error, poor in real-time performance, and heavy in follow-up data processing workload. With the rise of electronic technology, the emergence of new pressure sensors has laid the foundation for the technological innovation of ethernet pressure scanners.

In the 1960s, the application of electronic pressure sensors made a major breakthrough in ethernet pressure scanners technology. Multi-pressure sensors are composed into a whole test system, which realizes multi-point pressure measurement at the same time, and greatly improves the measurement efficiency and accuracy. However, the high cost of the system in this period and the fixed follow-up cycle limit its further promotion.

In the 1980s, the emergence of electronic ethernet pressure scanners measurement system is a revolution in pressure measurement technology. It uses silicon piezoresistive sensors, each pressure sensor corresponds to a channel pressure point, which solves the problem of pneumatic lag of mechanical ethernet pressure scanners, and improves the real-time and accuracy of pressure data collection in the system. Its acquisition rate can reach tens of thousands of points per second, and the error of the sensor can also be corrected through online real-time calibration technology, which greatly improves the measurement accuracy.

Modernization: Diversification and High Performance

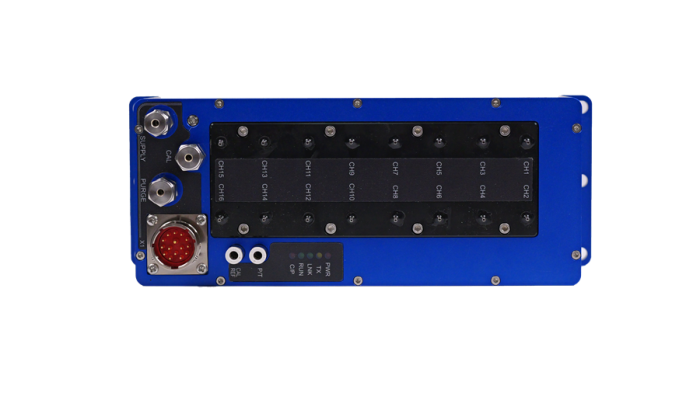

In recent years, ethernet pressure scanners technology has been in the direction of diversification and high performance. Taking PSI as an example, its 9000 series electronic ethernet pressure scanners, such as 9116, 9216, 9816 and ESP series multi-channel ethernet pressure scanners; Domestic enterprises such as Windtuner Technology have gradually completed the research and development of domestic ethernet pressure scanners. The measurement accuracy and products of 100% localized Windtuner ethernet pressure scanners are not inferior to foreign brands.

The history of ethernet pressure scanners is a history of evolution from specific field requirements to wide application in industrial production, from machinery to advanced electronic technology. In the future, with the continuous advancement of science and technology, ethernet pressure scanners is expected to play an important role in more fields, opening up a new world for the development and application of pressure measurement technology.