The precision requirements for pressure scanning valves in the industry usually vary according to different application fields. In general industrial applications, such as petroleum refining, chemical production or water treatment facilities, the accuracy requirements of pressure scan valves may be around ± 0. 5% FS (full scale). However, in more sophisticated scientific research fields, such as fuel management systems for devices or fluid control systems in high-energy physics experiments, the accuracy requirements are often raised to ± 0.1% FS or even higher to ensure the accuracy of experimental data and system stability.

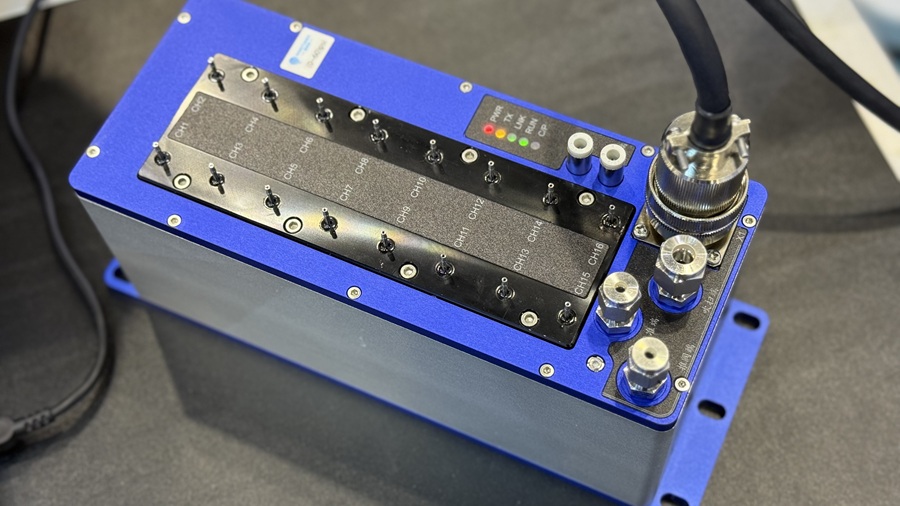

Windtuner Ethernet Intelligent Pressure Scanners stands out in the industry with its outstanding precision, reaching the advanced level of ± 0.05% FS and reaching the international advanced level. This achievement not only reflects the advancement of technology, but also marks a new height in the accuracy of pressure scan valves. The accuracy of ± 0.05% FS also means that Windtuner's pressure scan valve can provide stable and reliable pressure control, whether in the laboratory or in complex industries, ensuring that every operation achieves the expected effect, waste of resources due to errors and security risks.

In scientific research, small pressure changes may affect the accuracy of experimental results, which in turn affects the credibility of the entire study. For example, in wind tunnel tests, precise pressure control can simulate different flight conditions and help engineers optimize aircraft design. During the research and development of the engine, the high-precision pressure scan valve can monitor and accurately control the pressure distribution in the complex flow field inside the engine in real time to ensure that the combustion efficiency, thrust output and thermodynamic performance reach the state. Especially in the operation of extremely high temperature and pressure fluctuations in front of the turbine, the accuracy of ± 0.05% FS level means that subtle pressure changes can be captured, which is immeasurable for optimizing engine design, improving fuel economy, emissions and ensuring flight safety value. Therefore, high-precision pressure scan valve is the key to achieve high performance and reliability of the engine.

In short, the accuracy of the pressure scan valve is one of the key indicators to measure its performance, and WindtunerEthernet Intelligent Pressure Scanners has set an industry benchmark with an accuracy standard of ± 0.05% FS. In the field of scientific research and industry, this high-precision realization is not only a manifestation of technological innovation, but also an important force to promote scientific and technological progress and industrial upgrading. With the development of future technology, we have reason to expect that the accuracy of the pressure scan valve will be further improved, providing more possibilities for human beings to explore the unknown world and improve their lives.