Pressure Scanners core strengths:

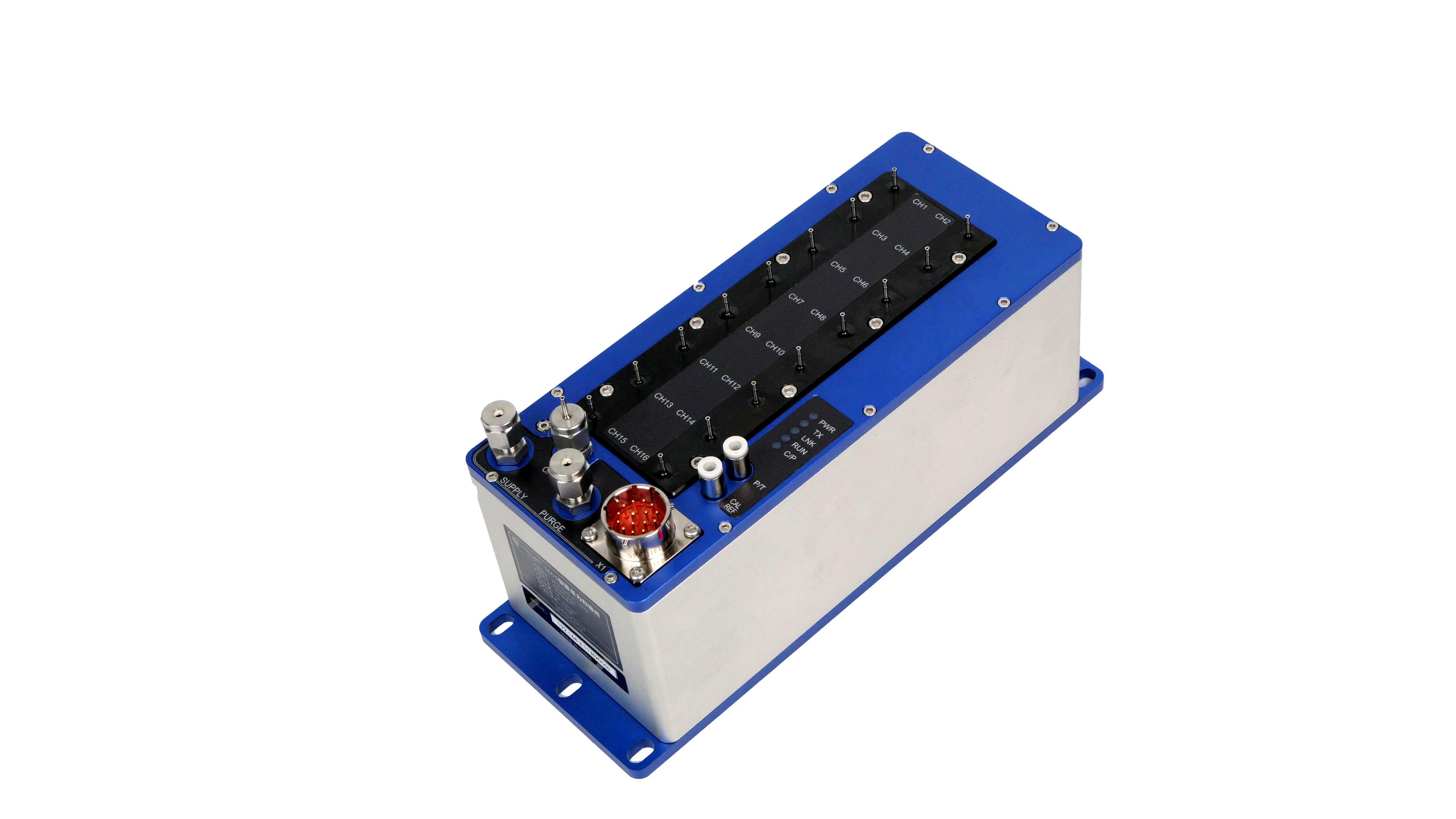

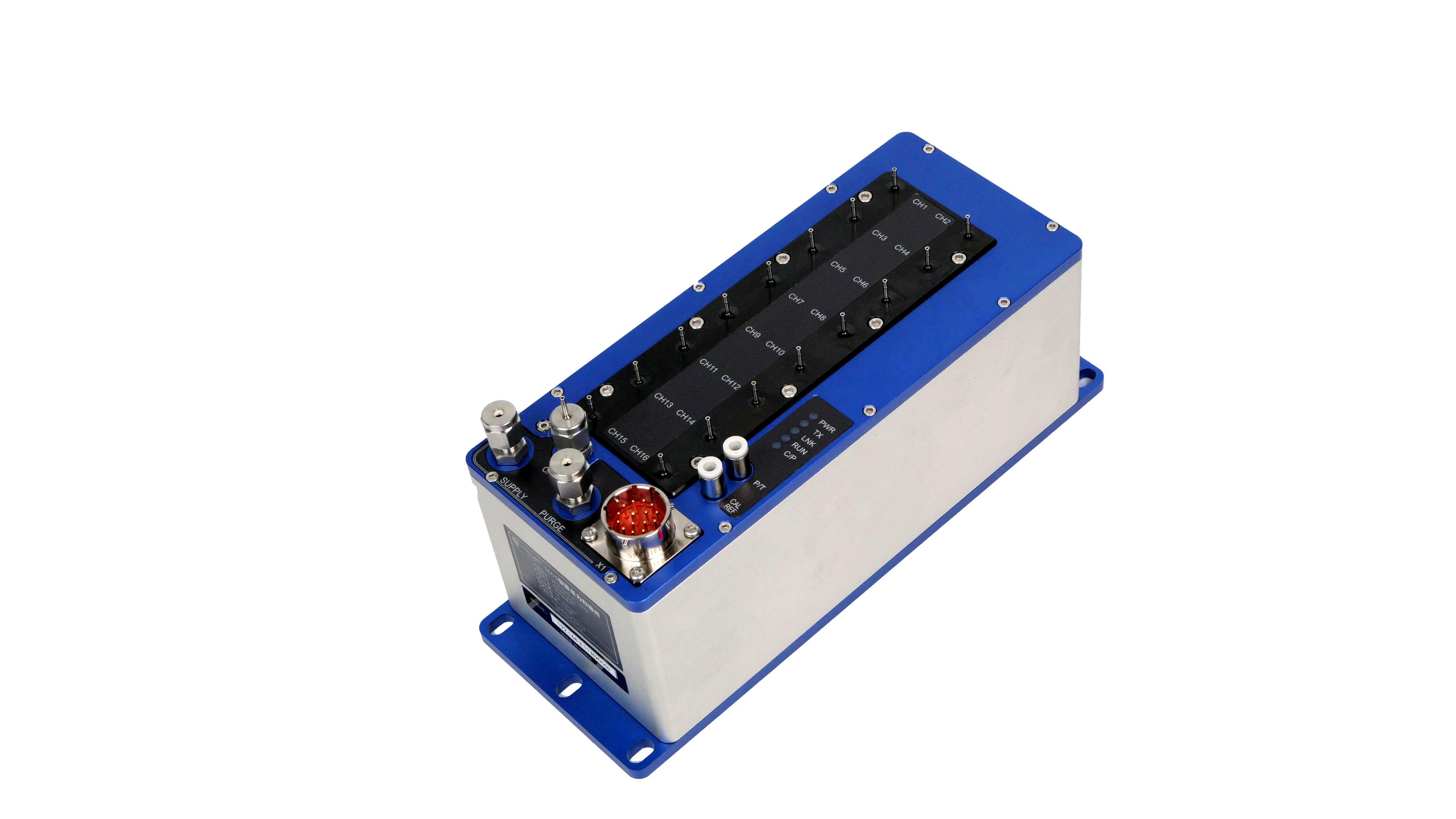

Windtuner Pressure Scanners is a multi-channel pressure measurement device that uses advanced scanning technology and high-precision sensors to realize multi-point synchronous pressure acquisition in complex flow field environments. It can scan pressure data at high frequency and obtain pressure changes from multiple test points in real time. Unlike traditional single-point pressure sensors, WindtunerEthernet Intelligent Pressure Scanners can comprehensively monitor the airflow and accurately analyze the pressure distribution of each measurement point by working with different types of probes (such as total pressure probes, five-hole probes, etc.).

Windtuner Pressure Scanners is a multi-channel pressure measurement device that uses advanced scanning technology and high-precision sensors to realize multi-point synchronous pressure acquisition in complex flow field environments. It can scan pressure data at high frequency and obtain pressure changes from multiple test points in real time. Unlike traditional single-point pressure sensors, WindtunerEthernet Intelligent Pressure Scanners can comprehensively monitor the airflow and accurately analyze the pressure distribution of each measurement point by working with different types of probes (such as total pressure probes, five-hole probes, etc.).

1. Accuracy and stability

With an accuracy of 0.05% FS, Windtuner Ethernet Intelligent Pressure Scanners can provide extremely accurate pressure data in different aerodynamic environments. In aero-engine testing, especially in the environment of high temperature, high pressure and complex airflow, accurate pressure data is very important for engine performance optimization and safety assessment.

2. Adapt to complex flow fields: meet various test requirements

WindtunerEthernet Intelligent Pressure Scanners' multi-channel synchronous acquisition capabilities make them excellent when dealing with complex flow fields. WindtunerEthernet Intelligent Pressure Scanners can provide a large amount of accurate pressure data for performance optimization, design verification and safety assessment in some complex experiments, such as engine test bench pressure test, wind tunnel test and inlet distortion test. Provide reliable data support.

In the traditional wind tunnel test, the adjustment of the angle of the test model and the change of the airflow make the test process usually more cumbersome, and the density of data acquisition is also limited. When WindtunerEthernet Intelligent Pressure Scanners is combined with the force measurement system, the pressure and angle data can be collected simultaneously during the model deflection process, so that a large amount of accurate pressure-angle correlation data can be obtained in one test, which greatly improves the test efficiency.

In addition, WindtunerEthernet Intelligent Pressure Scanners also has automatic calibration and pipeline purge functions. These designs ensure the stability of the equipment in high temperature and high pressure environments. WindtunerEthernet Intelligent Pressure Scanners can continuously provide accurate data in the pressure measurement of complex flow channels such as inlets and afterburners to ensure that the test process is not disturbed by changes in the external environment.

3. Multi-channel synchronous acquisition: greatly improving test efficiency

WindtunerEthernet Intelligent Pressure Scanners' multi-channel synchronous acquisition technology can synchronously acquire up to 200 channels of data in one test process. This efficient acquisition method is particularly important in many engineering applications. For example, the pressure tests of different components such as the engine's inlet, combustion chamber and turbine need to be carried out simultaneously, and WindtunerEthernet Intelligent Pressure Scanners can greatly improve the efficiency of data acquisition without reducing the measurement accuracy. Through this technology, engineers can obtain a large amount of accurate pressure data in a short period of time, and quickly conduct subsequent analysis and optimization.

The advantage of this technology is that it not only improves test efficiency, but also reduces the risk of data omission during testing. In complex experiments, pressure collection at multiple measurement points is often required synchronously. WindtunerEthernet Intelligent Pressure Scanners can ensure data synchronization at all measurement points and avoid analysis deviations caused by time differences.

Windtuner Technology's close cooperation with a number of aviation research and development institutions has enabled it to make significant breakthroughs in the field of aerodynamic testing and engine performance evaluation. WindtunerEthernet Intelligent Pressure Scanners' design concept comes from a deep understanding of complex aerodynamic environments, and every detail of it reflects Windtuner's pursuit of precision, stability and reliability. Through continuous innovation, Windtuner has successfully combined high-precision pressure measurement technology with aero-engine testing requirements, helping domestic and foreign aerospace companies improve R&D efficiency and promote technological progress in the industry.

With an accuracy of 0.05% FS, Windtuner Ethernet Intelligent Pressure Scanners can provide extremely accurate pressure data in different aerodynamic environments. In aero-engine testing, especially in the environment of high temperature, high pressure and complex airflow, accurate pressure data is very important for engine performance optimization and safety assessment.

2. Adapt to complex flow fields: meet various test requirements

WindtunerEthernet Intelligent Pressure Scanners' multi-channel synchronous acquisition capabilities make them excellent when dealing with complex flow fields. WindtunerEthernet Intelligent Pressure Scanners can provide a large amount of accurate pressure data for performance optimization, design verification and safety assessment in some complex experiments, such as engine test bench pressure test, wind tunnel test and inlet distortion test. Provide reliable data support.

In the traditional wind tunnel test, the adjustment of the angle of the test model and the change of the airflow make the test process usually more cumbersome, and the density of data acquisition is also limited. When WindtunerEthernet Intelligent Pressure Scanners is combined with the force measurement system, the pressure and angle data can be collected simultaneously during the model deflection process, so that a large amount of accurate pressure-angle correlation data can be obtained in one test, which greatly improves the test efficiency.

In addition, WindtunerEthernet Intelligent Pressure Scanners also has automatic calibration and pipeline purge functions. These designs ensure the stability of the equipment in high temperature and high pressure environments. WindtunerEthernet Intelligent Pressure Scanners can continuously provide accurate data in the pressure measurement of complex flow channels such as inlets and afterburners to ensure that the test process is not disturbed by changes in the external environment.

3. Multi-channel synchronous acquisition: greatly improving test efficiency

WindtunerEthernet Intelligent Pressure Scanners' multi-channel synchronous acquisition technology can synchronously acquire up to 200 channels of data in one test process. This efficient acquisition method is particularly important in many engineering applications. For example, the pressure tests of different components such as the engine's inlet, combustion chamber and turbine need to be carried out simultaneously, and WindtunerEthernet Intelligent Pressure Scanners can greatly improve the efficiency of data acquisition without reducing the measurement accuracy. Through this technology, engineers can obtain a large amount of accurate pressure data in a short period of time, and quickly conduct subsequent analysis and optimization.

The advantage of this technology is that it not only improves test efficiency, but also reduces the risk of data omission during testing. In complex experiments, pressure collection at multiple measurement points is often required synchronously. WindtunerEthernet Intelligent Pressure Scanners can ensure data synchronization at all measurement points and avoid analysis deviations caused by time differences.

Windtuner Technology's close cooperation with a number of aviation research and development institutions has enabled it to make significant breakthroughs in the field of aerodynamic testing and engine performance evaluation. WindtunerEthernet Intelligent Pressure Scanners' design concept comes from a deep understanding of complex aerodynamic environments, and every detail of it reflects Windtuner's pursuit of precision, stability and reliability. Through continuous innovation, Windtuner has successfully combined high-precision pressure measurement technology with aero-engine testing requirements, helping domestic and foreign aerospace companies improve R&D efficiency and promote technological progress in the industry.

Windtuner Technology's Pressure Scanners system uses high-sampling rate technology to capture transient airflow changes. For example, in the inlet distortion test, through the sampling rate of 500Hz, Pressure Scanners can accurately capture small changes in airflow distribution and generate real-time pressure cloud images. The application of this technology enables engineers to monitor the "breathing" status of the engine in real time during flight, find problems in time and take countermeasures to ensure the safety of engine operation.