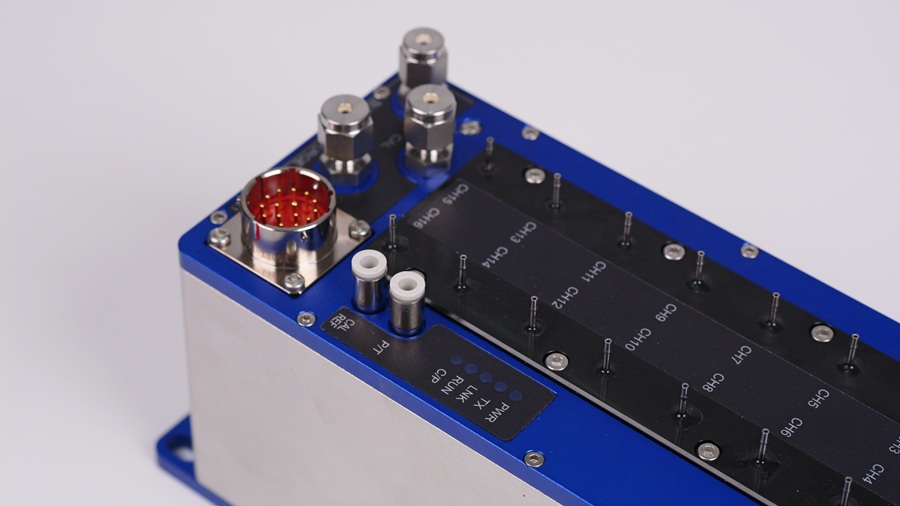

As the power generation equipment with the highest heat-power conversion efficiency, the performance optimization of gas turbines is highly dependent on the accurate measurement of flow field parameters. The Ethernet Intelligent Pressure Scanners independently developed by Windtuner Technology can capture small pressure fluctuations inside the gas turbine in real time by integrating 16 high-precision pressure sensor modules, with an accuracy of up to ± 0.05 FS and a sampling frequency of 0-500Hz, which can meet high temperature, high pressure, Dynamic monitoring requirements in high stress environments. In a heavy-duty gas turbine research and development project, Windtuner Technology used Intelligent Pressure Scanners to work together with the thermocouple collector to realize the simultaneous collection of key parameters such as the total temperature, total pressure, and static pressure of the combustion chamber, improving combustion efficiency and reducing carbon emissions. Provides data support.

In addition, Windtuner Ethernet Intelligent Pressure Scanners also has maintenance-free pneumatic valve circuit system and automatic full-scale calibration function, which greatly shortens the test cycle. For example, in a small gas turbine project, its supporting WindLabX measurement and control software shortens the calibration time by more than half, significantly improves the efficiency of data acquisition, and reduces R&D costs.

Three-dimensional flow field testing: solving design problems under complex working conditions In the process of gas turbine research and development, the inlet distortion and uneven flow field distribution in the combustion chamber directly affect the performance and reliability of the equipment. Windtuner technology can realize dynamic visual monitoring of the internal flow field of gas turbines through three-dimensional flow field testing technology, combined with Ethernet Intelligent Pressure Scanners, aerodynamic probes and motion control systems. For example, its micro five-hole probe can have a diameter of 0.2 mm and is manufactured using micron-level 3D printing technology. It can penetrate into small spaces such as turbine blade gaps, capture three-dimensional speed and pressure distribution data, and provide a scientific basis for the optimal design of the combustion chamber.

In addition, Windtuner Technology also provides a series of customized measurement and control solutions to meet the special needs of different customers in gas turbine research and development. From flow field simulation to real machine testing, from data analysis to performance optimization, Windtuner Technology has always worked closely with customers to jointly overcome technical problems and promote the continuous progress of gas turbine technology. In the future, with the advancement of the "dual carbon" goal, the gas turbine industry will usher in a broader space for development.

Windtuner Technology will continue to deepen the flow field measurement and control technology, use localization innovation as the engine, promote the upward development of my country's high-end equipment manufacturing, and inject lasting impetus into energy strategic transformation and green development. As a leading enterprise in the field of flow field measurement and control, Windtuner Technology will continue to uphold the concept of innovation, pragmatism and efficiency, continuously improve product performance and service quality, and provide more comprehensive and professional measurement and control support for the research and development of gas turbines.