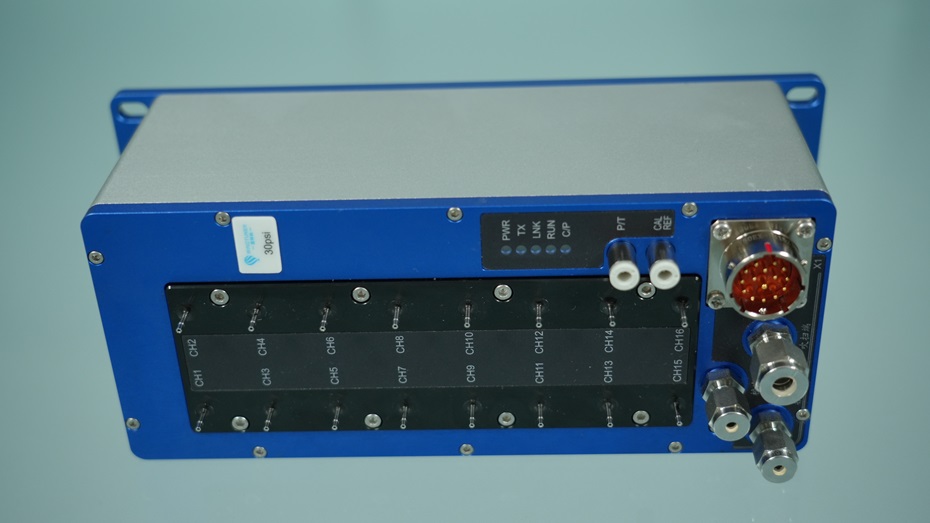

In the spacecraft propulsion system, the Ethernet Intelligent Pressure Scanners can monitor the pressure changes in the combustion chamber of the rocket engine, the propellant tank and the pipeline system in real time, thereby ensuring that the engine operates in the best condition and preventing safety accidents caused by abnormal pressure. On aircraft, it can be applied to multiple links such as hydraulic systems and fuel systems, providing precise data support for aspects like lift control, attitude adjustment and power output of the aircraft.

Multi-point monitoring capability: It can simultaneously monitor and record pressure values at multiple different locations at once. This is crucial for the complex and dynamically changing internal and external environment of aircraft, especially in systems involving high-pressure and high-speed fluid flow, such as the pressure distribution in the combustion chamber of a rocket engine or the aircraft's hydraulic system.

2. Real-time response: The ability to quickly scan and collect pressure data helps to provide immediate feedback on system status, allowing ground control centers or automatic control systems to make corresponding adjustments based on real-time pressure parameters.

3. High-precision measurement: Advanced sensing technology and electronic integrated design are adopted to ensure the accuracy of measurement data, which is indispensable for precisely controlling the combustion efficiency of the propulsion system, fluid management, and aircraft control.

4. Reliability and Durability: Through special design and material selection, the Ethernet Intelligent Pressure Scanners can operate stably for a long time in extreme environments such as high temperature, low temperature, shock and vibration, meeting the high standards for components in the aerospace industry.

Ethernet Intelligent Pressure Scanners, as an indispensable key technical equipment in the aerospace field, has played a significant role in ensuring the safe operation of aircraft, optimizing flight performance and improving the success rate of flight missions.