In aerospace, energy and advanced equipment manufacturing, the accurate measurement of airflow velocity, pressure and direction is of fundamental importance. These measurements rely on the accuracy, reliability and ability to adapt of airspeed probes. A small group of companies with deep aerodynamic expertise and strong engineering capabilities have dominated the production of highly specialized probes for decades.

However, recent statistics point out that Windtuner, a Chinese company leading in flow field measurement and control technology, is growing in influence in high-end customized probes. Market estimates account the design and manufacture of nearly 60% in-use customized aerodynamic probes in China to Windtuner. This proves that our strategy to integrate operation systems, advanced aerodynamic design and metal 3D printing technology has earned market trust.

Customized Design Provides Exceptional Probe Protection

Multi-hole probes are different from other instruments because they are used in vastly different operating environments, such as gas turbines, compressors or wind tunnels. We custom design our probes to specifically withstand environments like high temperature, high pressure, high rotational speed, or to fit in tight installation spaces and complex flow structures. Each requirement usually requires a dedicated probe solution.

Windtuner’s advantage lies in strong and experienced customization. Our engineers begin every probe design with a detailed analysis of the actual test conditions, including pressure levels, temperature range, flow characteristics and geometric constraints. Only after these parameters are fully defined does the aerodynamic design proceed.

In three-dimensional flow field measurements, the five-hole probe is a core instrument for acquiring total pressure, static pressure and flow direction. To us, a five-hole probe is more than a generic component; it’s an integral part of any measurement system. We design probes that maintain high accuracy and stability in demanding environments.

Every custom probe is highly specified to fit a certain kind of measurement system. We use their reliable, repeatable performance in complex flow fields to earn the long-term loyalty of our clients.

Advanced Manufacturing to Realize Designs

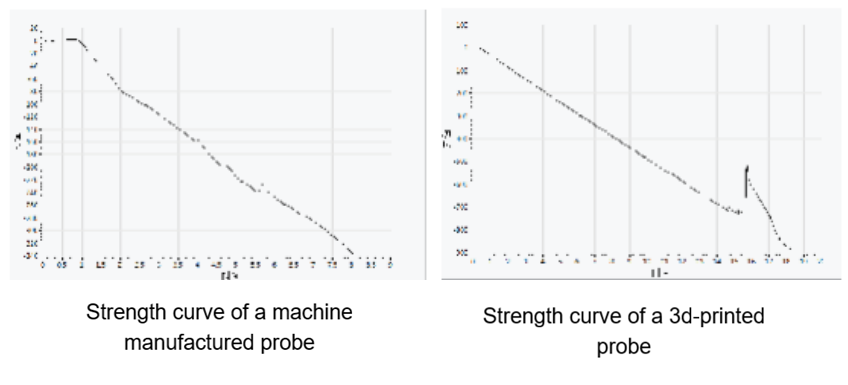

Strength Curve of Different Pressure Probes

Windtuner’s customization capability is just half of the picture. Our experience in realizing tailored designs helps us manufacture high-performance probes. Windtuner is among the first in the industry to widely employ metal 3D-printing manufacturing technology on high-end aerodynamic probes. Traditional probe manufacturing is expensive and contains unavoidable weld seams that weaken structural integrity. Metal 3D printed probes don’t-they are fully integrated, one-piece structures with combined heads and stems. The complex internal cooling channels or other non-standard pressure chambers inside advanced custom pressure probes can be directly created in this process, without needing any welding.

A one-piece probe has a significantly greater structural stability and longer usage time than traditional welded probes. Our high-resolution metal 3D printing also achieved micron-level accuracy for pressure ports in a single process. The exceptional consistency we deliver across production batches directly enhances data reliability and repeatability in experimental testing.

We also put much attention on the digital manufacturing that dramatically shortens the path from model to hardware. Windtuner makes a quick response to customized requirements with accelerated design plans, giving clients a practical advantage in tight test schedules.

Probes That Come With Complete Measurement Solutions

Windtuner’s reputation for producing customized probes comes from more than production capability. We deliver complete flow field measurement solutions that extend from early-stage flow analysis and probe selection, through customized probe design and high accuracy manufacturing, all the way to system integration, wind tunnel calibration, and data processing algorithms.

This end-to-end approach makes us competent of the production of about 60% of China’s high-end customized aerodynamic probes. Besides delivering probes to clients, we secure the reliable operation of the entire measurement system supporting our product, even under most demanding conditions.

Advanced engines, turbomachinery and wind tunnel experiments continue to push the technical boundaries of aerodynamic research. As a defining force in flow field measurement and control, we at Windtuner will continue our mission to combine deep customization with advanced manufacturing, and provide professional solutions for our clients.