A Windtuner 3D-Printed Five-Hole Probe

A representative research project highlights the value of five-hole probes in demanding measurement scenarios. To address the challenge of measuring the outlet flow field of a turbine guide vane, researchers developed a broadly applicable data-reduction methodology for five-hole probes and implemented it in a dedicated calculation program. The core of this program lies in efficiently and accurately resolving the nonlinear mapping between the five pressure signals and the corresponding flow parameters. Applied to the outlet flow measurement of a specific guide vane, the method delivered clear and trustworthy two-dimensional and three-dimensional flow field maps. These results provided direct, actionable data for analyzing flow structures and evaluating guide vane aerodynamic performance, demonstrating strong practical impact in both research and engineering design.

As five-hole probe technology continues to advance, professional manufacturers such as Windtuner have further unlocked its potential through robust customization capabilities. Windtuner designs probes tailored to specific experimental requirements, including miniature flow passages, targeted Mach number ranges, and extreme temperature environments. By optimizing probe geometry, structural strength, and material selection—such as the use of high-temperature alloys—Windtuner delivers solutions that integrate seamlessly with non-nulling measurement methods and automated scanning systems. Windtuner’s precision manufacturing process guarantees consistency in probe aerodynamic shape and pressure port geometry, forming the physical basis for high-accuracy measurements.

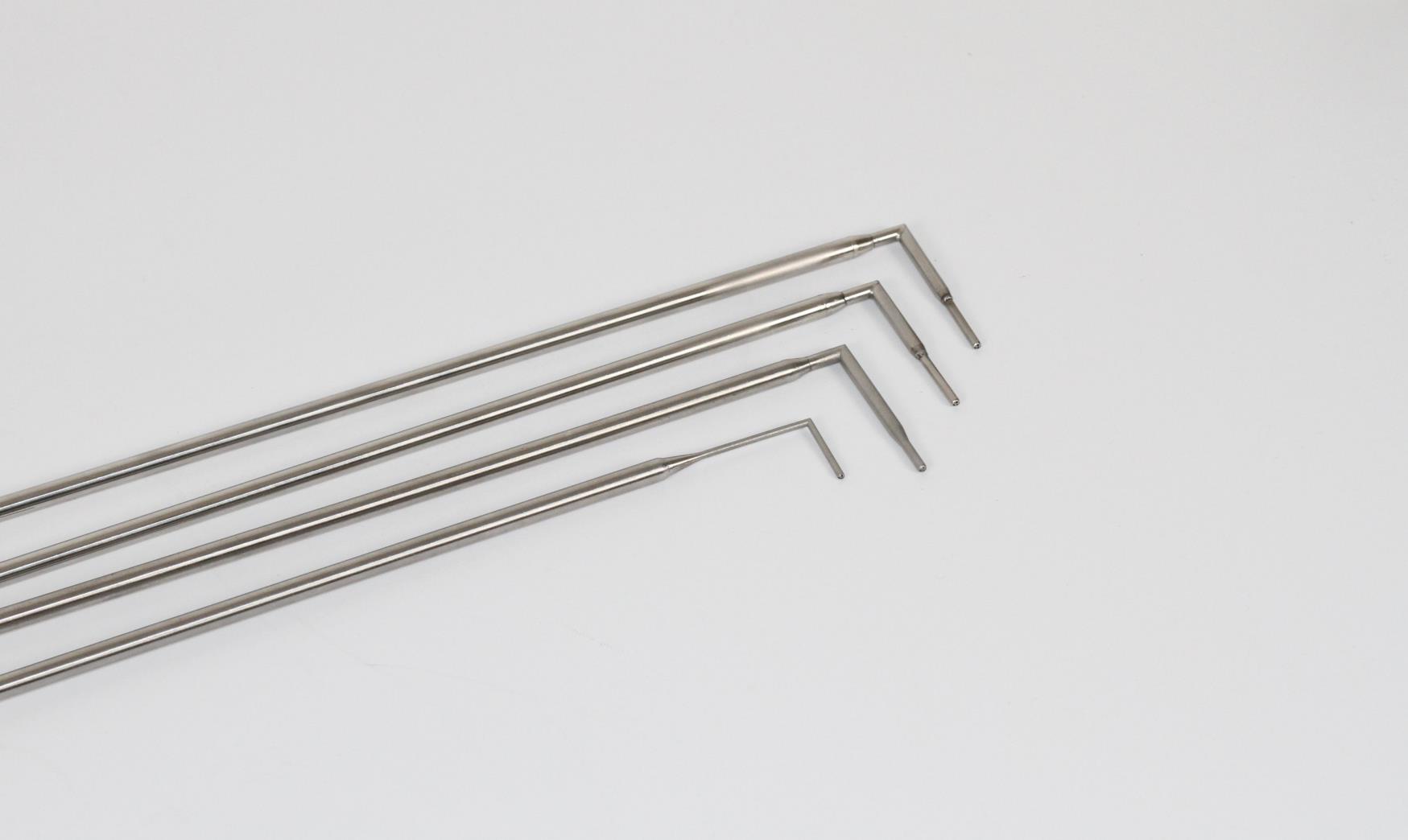

L-Shaped Airspeed Probe

In practical applications, researchers select suitable data-reduction models based on flow regimes, whether subsonic or supersonic. Among these approaches, the non-nulling measurement method has gained particular attention for its efficiency. This method calculates flow parameters through iterative algorithms even when the probe is not perfectly aligned with the incoming flow, eliminating time-consuming mechanical alignment procedures and accelerating the overall testing process.

Advanced automated wind tunnel testing systems increasingly combine non-nulling measurement methods with electric actuators, automated scanning, and real-time data acquisition and processing. In these systems, probes move along predefined grids while rapidly collecting five-hole pressure data at each measurement point. High-efficiency algorithms then compute flow parameters in real time. This integrated approach significantly increases test speed, reduces wind tunnel operating costs, and minimizes human-induced errors, making it an effective way to maintain—and often improve—measurement accuracy.

Windtuner’s long-standing excellence in customized five-hole probe design has earned broad recognition from researchers across disciplines. Looking ahead, Windtuner aims to collaborate with more scientific teams worldwide, delivering accurate, trustworthy, and cost-effective flow measurement and control solutions that advance experimental research and engineering innovation.