In F1, wind tunnels are also about efficiency. Teams are restricted not only in total testing hours but also in the number of runs and occupancy time. Thus, for efficiency’s sake, F1 teams do not test full-size cars in wind tunnels. They implement carefully engineered 60%-scale models to replicate real-world aerodynamic behavior. These models feature rotating wheels, a moving ground belt to simulate the track surface, and precise ride-height and attitude control to represent pitch, roll, yaw, and steering effects. Crucially, these limits are applied on a sliding scale: teams lower in the championship standings are allowed more wind tunnel aerodynamic testing time than those at the front. As a result, success in F1 aero development depends less on how much wind tunnel time a team has and more on how intelligently that time is used. Frankly, Windtuner does not use wind tunnels with the notion that time is limited. Without the need for competition balancing, a wind tunnel is best used intelligently and patiently, leading to high quality products. When we test our pressure scanners, we use time extensively and ensure that it is fully calibrated. Prototypes require 10000 hours of examination before they can reach mass production.

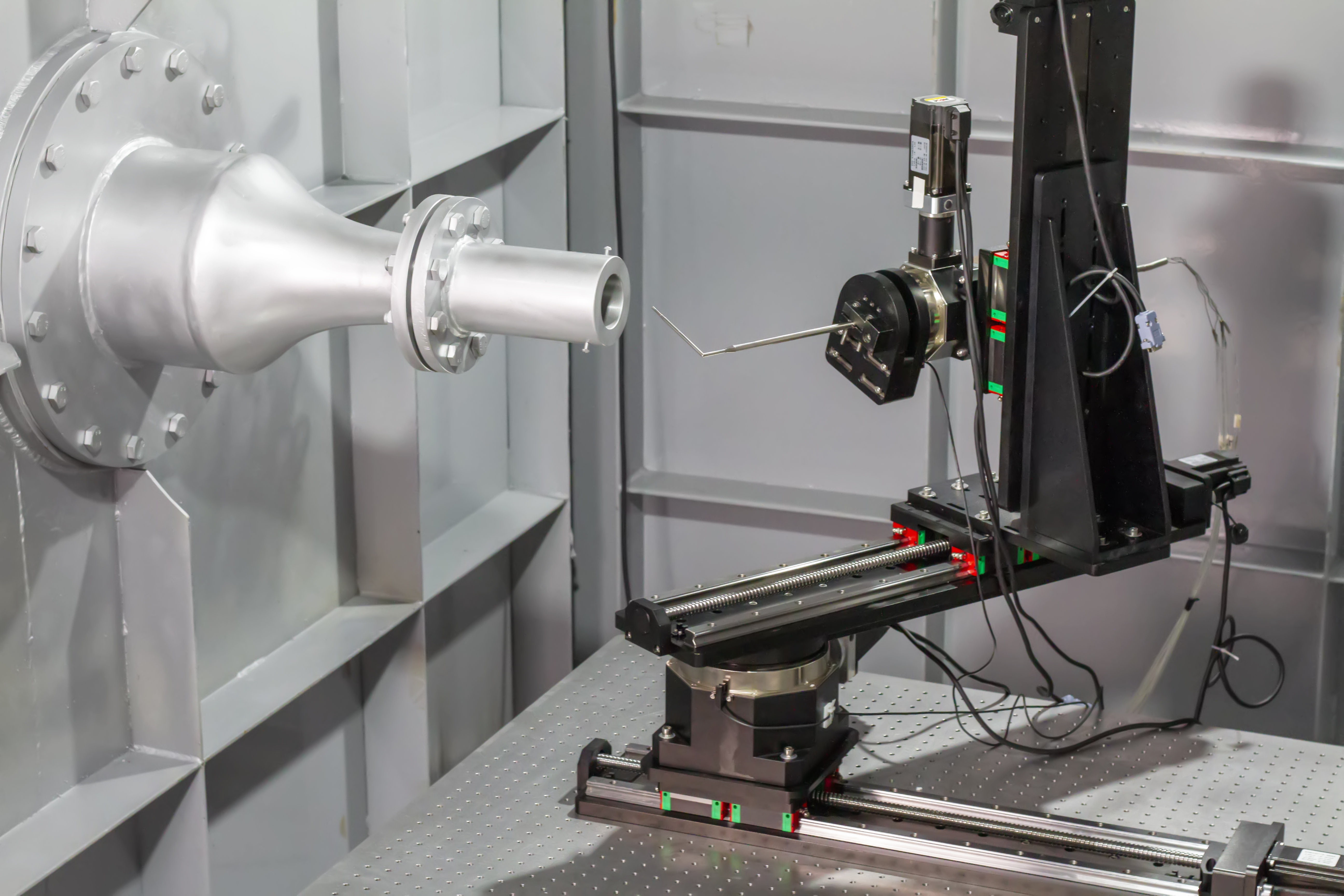

Correlation has become one of the most critical competitive battlegrounds in Formula 1. Engineers must ensure that results from CFD, wind tunnel testing, and on-track measurements align closely. When correlation breaks down, teams risk developing upgrades that perform well in simulation but fail to deliver in races. This has elevated the importance of precise pressure measurements, accurate probe placement, robust calibration procedures, and stable environmental control within the tunnel. Inside or outside the strict limitations of F1, a good set of pressure probes and pressure scanners would help car models go a long way.

Wind tunnels offer a much higher level of control and repeatability than tests done in circuits. Track aero tests are limited in scope, affected by weather and ambient conditions, and restricted by sporting regulations. In contrast, wind tunnels allow engineers to isolate variables, run back-to-back comparisons, and explore aggressive concepts safely and efficiently. A wind tunnel can complete the vehicle’s vast majority of aerodynamic development before it ever reaches a racetrack.

In a progressive view, we see the role of wind tunnels in Formula 1 evolve rather than diminish. Teams are integrating CFD, wind tunnel data, and data-driven optimization tools deeper into their development system. This is similar to how we at Windtuner built our comprehensive pressure measurement system with measurement control software, pressure scanners and custom airspeed probes.

In modern Formula 1, wind tunnels are part of the pair of hands that influence the competitive order. In the view of broad aerodynamics research and testing, we see wind tunnels as the testing center of precision instruments. Wind tunnels have a larger part and more important duties in aerodynamic research because they do not have usage time limits like those in F1 regulations.

Automation, smarter test planning, and tighter integration between simulation and physical testing will define the next phase of aerodynamic development. In this environment, wind tunnel laboratories and technology providers share the common goal to deliver trustworthy data without compromise. Windtuner advances this goal by using wind tunnels to calibrate intelligent pressure scanning accuracy, and present measurement solutions that meet the demands of today’s most performance driven aerodynamic researches.