In flow measurement, the accuracy of a pressure scanner is a basis number for many other indicators. It shows how far a laboratory can push its experiments with credible data. For example, Windtuner pressure scanners have the accuracy of ±0.05% FS, a considerably high accuracy and absolutely adequate for the actual requirement for many aerodynamic projects. Above this, and laboratories step into a different class of measurement capability that might not be necessary or realistic for their project. Cutting-edge aerodynamic research facilities-such as F1 labs or military fighter companies-may have much higher standards. So it is important to ‘know thyself’:Experienced engineers do not purely ask for higher levels of accuracy. They ask what level of accuracy is actually needed, and how to best apply the accuracy of different pressure measurement instruments under context.

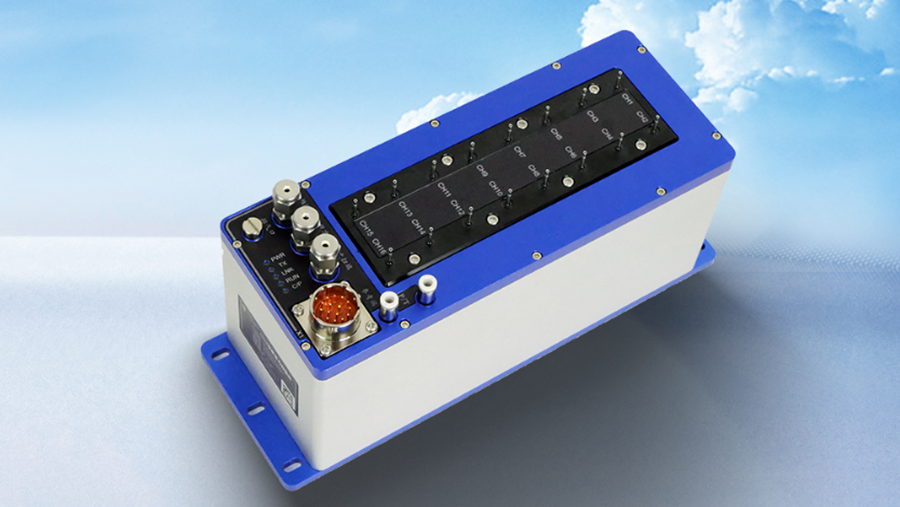

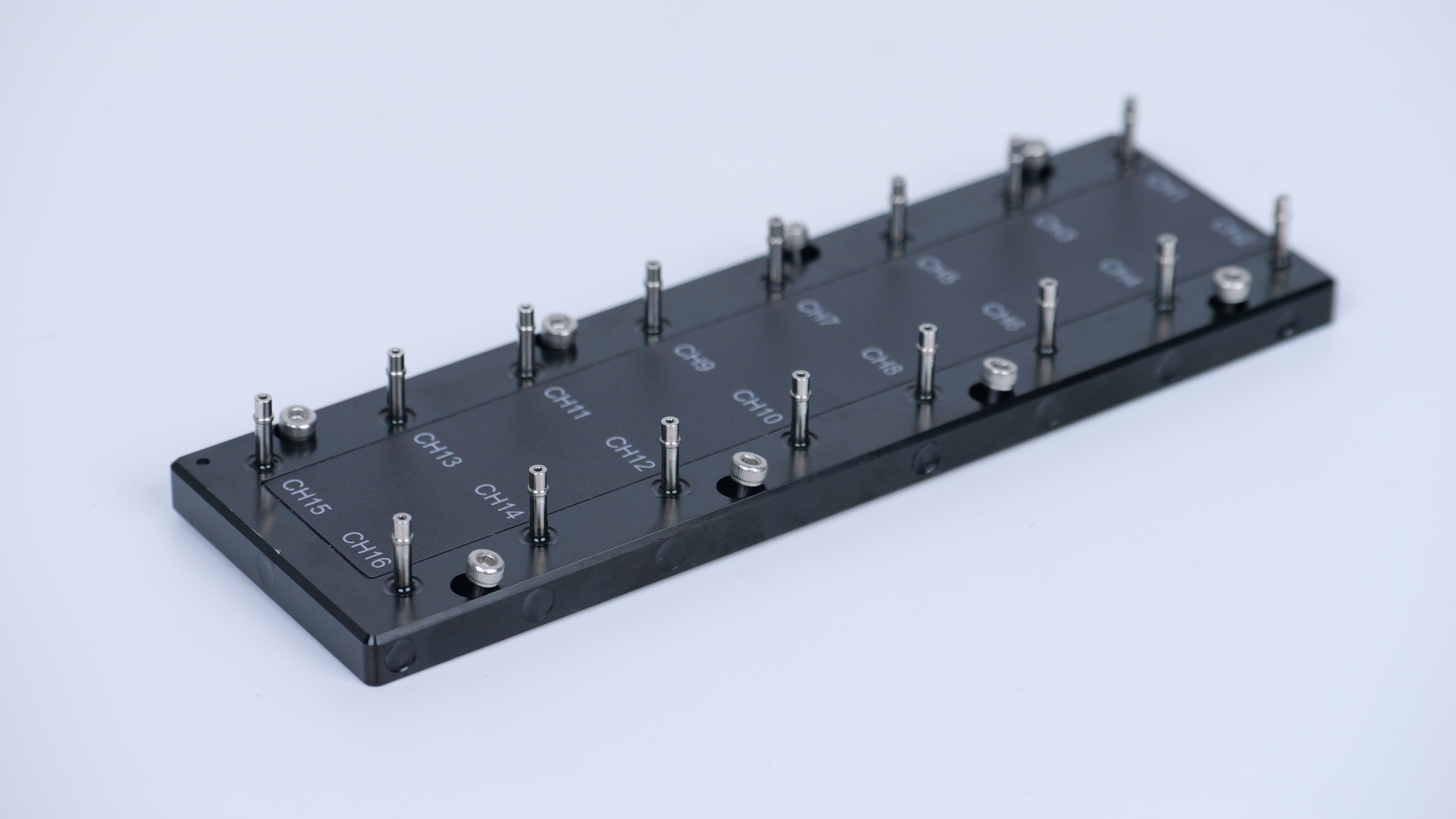

The Windtuner Ethernet Intelligent Pressure Scanner

Experienced engineers do not purely ask for higher levels of accuracy. They ask what level of accuracy is actually needed, and how to best apply the accuracy of different pressure measurement instruments under context.

When Accuracy Is Non-Negotiable

There are tests where accuracy directly determines whether the data is usable. Engine inlet distortion testing, cascade wind tunnel experiments, and multi-hole probe calibration operate in regimes where pressure differences are small, gradients are sharp, and margins are narrow. In these conditions, measurement uncertainty compounds rapidly. A pressure scanner that drifts, even slightly, distorts velocity reconstruction and flow angle calculation in ways that no post-processing can fully correct.

Here, accuracy as high as ±0.05% FS is key to the entire outcome of an aerodynamic project. It defines the lower bound of credible data and sets the ceiling for what the test can reveal. Without it, comparisons between runs become unstable, calibration curves lose coherence, and results fail to stand up under review.

Windtuner pressure scanners were built for exactly this tier of application. With accuracy rated at ±0.05% FS, they support high-resolution measurements without being overpriced and inconsiderate for the actual needs of our clients. Instead, we employ rigorous calibration methods and powerful systematic measurement solutions to ensure the reliability and quality of the data collected combined with a good price.

When Accuracy Alone Is Not Enough

Problems arise when accuracy is treated as a substitute for system design. A pressure scanner can meet an excellent specification and still deliver mediocre results if calibration, synchronization, and probe handling are neglected.

In automated wind tunnel testing, timing matters as much as resolution. Pressure data must align with probe position, actuator motion, and test conditions. If the measurement system does not have good enough synchronization, accuracy will suffer degrade even when the sensor itself performs correctly. Windtuner pressure scanners support IEEE1588V2-2008 Precision Time Protocol to keep data precision in the process of measurements. The same applies to calibration. A scanner that is rarely calibrated, or calibrated outside the conditions it actually operates in, quickly loses the advantage its specification implies. Windtuner pressure scanners are carefully calibrated in wind tunnel laboratories before distribution, and they contain self-purging functions, safeguards for its precision.

This is why accuracy is not an attribute granted at purchase. A pressure scanner or multi-hole probe needs to be carefully preserved and maintained to keep its performance. Calibration wind tunnels, disciplined workflows, and integrated measurement and control software determine how accurate an instrument is in practice.

When Accuracy Stops Being the Bottleneck

There is also a point where increasing accuracy no longer improves insight. In many development tests, the dominant uncertainties come from flow unsteadiness, model geometry, installation tolerance, or probe positioning. Once those become the major error factors, pushing sensor accuracy further yields diminishing returns.

In these cases, the smarter investment is not a tighter specification, but a more stable system. Improving probe repeatability with an Electric Actuator, standardizing calibration procedures, or reducing human intervention often produces cleaner, more actionable data than upgrading sensors alone.

Accuracy still matters here — but as part of a balanced measurement strategy rather than the headline feature.

Using Accuracy with Intent

Capable aerodynamic laboratories do not chase accuracy blindly. They apply ±0.05% FS accuracy with calibration and synchronization support, and recognize when system-level improvements deliver more value than tighter numbers.

Windtuner approaches accuracy from this practical standpoint. Pressure scanners, probes, calibration wind tunnel capability, and measurement and control software are developed as a connected measurement chain. This allows accuracy to remain consistent from calibration through testing and analysis, a factor equally important to how high the level of accuracy is.

±0.05% FS accuracy actually matters because it is a great indicator for a laboratory to trust, higher than what most measurements need, and easy to use and maintain. Knowing when accuracy does the job and when other factors take precedence — is what turns high-end hardware into reliable engineering results. Windtuner pressure scanners can offer ample levels of accuracy for your academic or industrial needs at the cost most fair and advantageous to you.