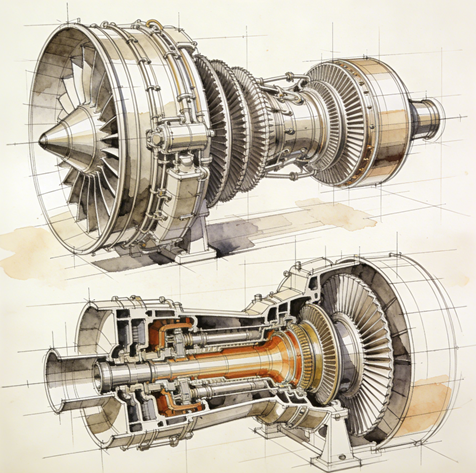

Turbine Testing is a Challenging Mission

Gas turbines work under heat and considerable pressure. Therefore performance testing of small gas turbines involves simultaneous acquisition of multiple aerodynamic and thermal parameters, each of which directly affects efficiency evaluation and operational safety. These tests are typically conducted in high-temperature, high-pressure environments that simulate environments gas turbines constantly work in. Measurement devices must equally maintain long-term stability and accuracy. Conventional instruments often struggle under such conditions, increasing uncertainty and operational risk. Clients therefore require a solution that delivers accurate data acquisition while remaining trustworthy in harsh test environments.

Windtuner’s Integrated Testing Solution

Windtuner delivers a complete flow field measurement and control solution designed specifically for small gas turbine performance testing. By integrating high-performance probes, Ethernet Intelligent Pressure Scanners, and advanced measurement and control software, Windtuner systems drive higher testing efficiency and data quality throughout the experiment lifecycle.

In gas turbine testing, total pressure and total temperature probes play a decisive role. Windtuner probes are engineered for high-temperature operation and calibrated in Windtuner’s calibration wind tunnel laboratory accredited by CNAS. These probes deliver stable, real-time measurements under elevated pressure and temperature, forming a reliable foundation for downstream analysis.

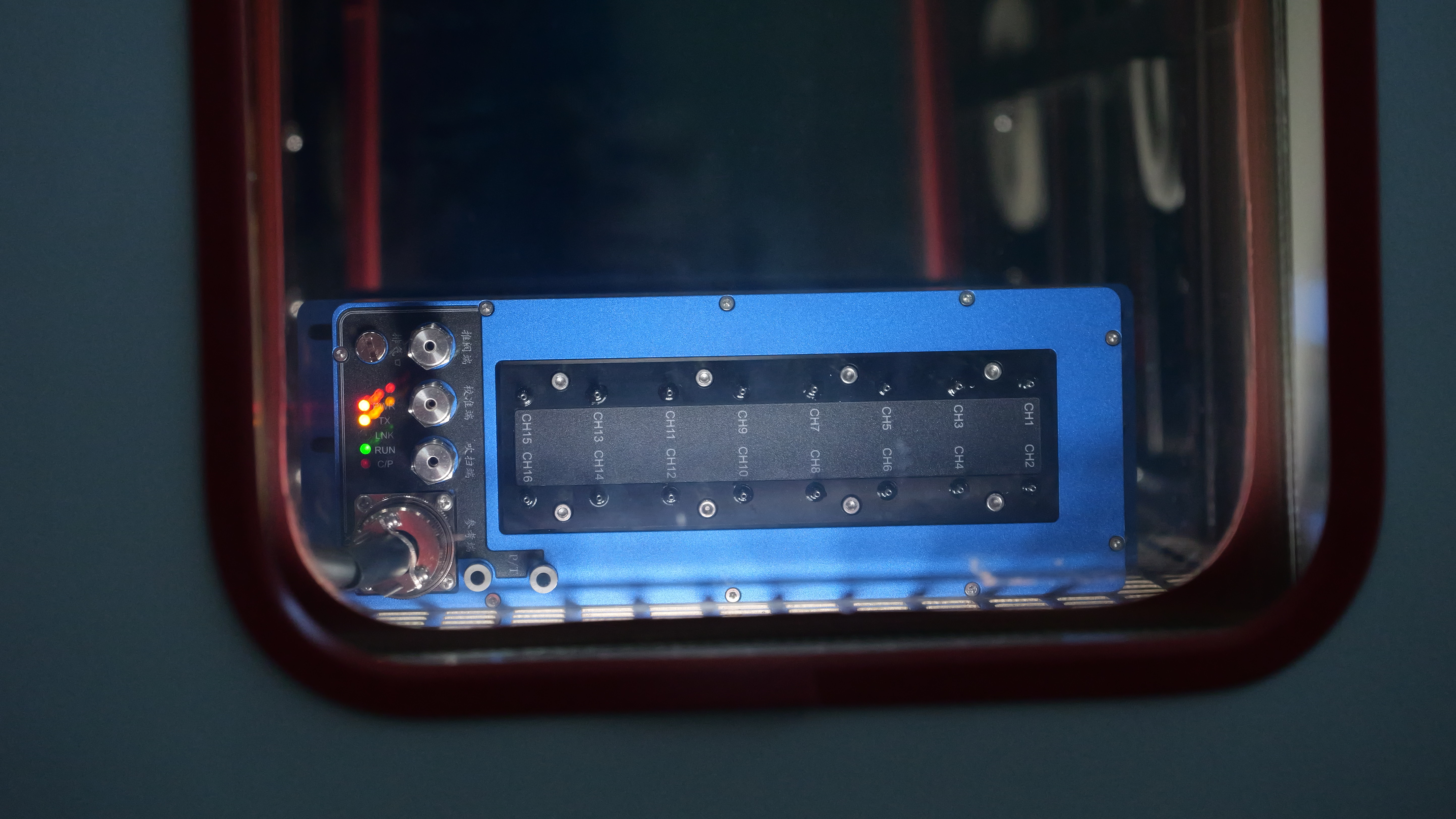

At the core of the system, Windtuner pressure scanners collect and process multi-channel pressure data with an accuracy of ±0.05% FS. The Ethernet Intelligent Pressure Scanner features automated calibration, high-frequency sampling, and robust pneumatic architecture, reducing manual intervention while driving repeatable and accurate test results. Engineers gain finer control over flow conditions, allowing test environments to closely replicate real operating states.

High-temperature probes designed with advanced ceramic and high-temperature alloy materials extend measurement capability into extreme thermal zones. These probes maintain structural integrity and signal stability, enabling accurate gas temperature measurement critical to turbine performance optimization.

To complete the data chain, thermocouple acquisition instruments and analog signal acquisition systems capture temperature and auxiliary signals in real time. Together, they maintain synchronized, high-integrity data transmission across the entire test setup, even during long-duration runs.

WindLabX Measurement and Control Software

At the system level, WindLabX measurement and control software serves as the operational hub. The platform visualizes real-time test data, manages multi-device networking, and supports customized analysis functions tailored to specific engine test benches. Engineers can track parameter trends instantly, identify anomalies early, and adjust test strategies with confidence.

Driving Reliable Gas Turbine Development

By deploying Windtuner’s integrated solution, clients significantly improve both testing efficiency and measurement accuracy in small gas turbine performance evaluation. The combined system—built around pressure scanners, pneumatic probes, and customized measurement and control software—empowers researchers to conduct reliable testing in complex high-temperature, high-pressure environments. This capability directly contributes to improved gas turbine reliability, higher operational efficiency, and accelerated development cycles.

As small gas turbines continue to expand into new application scenarios, Windtuner pressure scanners and flow field measurement solutions remain a dependable foundation for advanced engine testing and performance validation.