Across aerospace programs and aerodynamic research labs, the pressure scanner market has quietly grown into its own specialized segment. Whether in university wind tunnels, compressor rigs for engines, or small gas turbine test benches, 16-channel equipment has become the standard for flow-field pressure measurement. Yet devices that look identical on paper often deliver dramatically different performance, reliability, calibration consistency, and service life. The real gap only becomes clear once experiments start running.

Pressure scanners rarely show differences on the outside. But their structure and craftsmanship are rarely the same on the inside. Many devices highlight familiar selling points such as high accuracy, multi-channel design, or fast response. The actual distinction starts with the internal architecture. Windtuner’s Ethernet Intelligent Pressure Scanner integrates sixteen independently packaged pressure sensor modules, each equipped with a microprocessor, a pressure sensor, a temperature sensor, and an EEPROM storing calibration data. Every channel does its linear pressure and temperature compensation independently. Lower-end products continue to use board-level unified compensation, which often struggles with temperature stability or long-term consistency. The ability to replace an individual module is even more critical for high-accuracy test environments. When a single channel drifts or fails, researchers do not lose the entire instrument.

The real separation begins with the calibration system. Experienced engineers agree that the accuracy of a pressure scanner comes from more than just sensors; calibration defines its behavior throughout operation. Windtuner pressure scanners support internal zero calibration, internal full-scale calibration, and user-defined multi-point calibration. Windtuner also maintains a certified testing center capable of calibrating pressure scanners and other monitoring devices. The center calibrates instruments from Windtuner and from other brands, and its results are internationally recognized. Many competitors rely solely on external calibration facilities, lack multi-point calibration capabilities, and operate without unified calibration standards. When temperature shifts or long-duration tests occur, the resulting drift accumulates quickly. In compressor characteristic tests, scanners without multi-point calibration generate systematic errors that force researchers to repeat experiments. Windtuner’s intelligent pressure scanners reduce the need for duplicate runs and help clients regain testing efficiency.

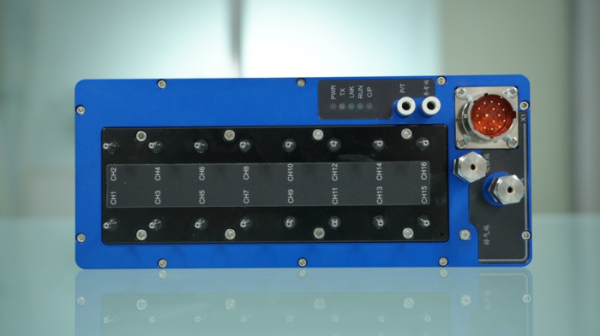

A Windtuner Ethernet Intelligent Pressure Scanner

Valve-body structure and route switching determine stability and service life. In many designs, this system receives little attention despite being the backbone of device reliability. Windtuner develops a maintenance-free pneumatic valve-route system combined with a push-valve pressure design. This architecture sustains reliability during high-frequency switching and avoids sticking valve cores, slow back-pressure recovery, or increased channel drift. For aerospace R&D, these issues directly distort data and can compromise the usability of entire experiments.

Time synchronization defines whether a device is simply “usable” or truly “research-grade.” Modern experiments rely on synchronized operation across many instruments. High-speed wind tunnel tests, dynamic pressure measurements, and multi-device sampling all depend on precise timestamps. In some R&D scenarios, hundreds of pressure points must be sampled at the same moment, making synchronization essential. Windtuner pressure scanners adopt IEEE1588 Precision Time Protocol (PTP), synchronizing time with a host system and delivering accurate timestamped data streams to all local devices. This accuracy far exceeds NTP-based synchronization and satisfies high-level research requirements. Many scanners from competing brands still rely on lower-accuracy NTP, lack hardware triggering, or do not output timestamps at all, which prevents their data from aligning across devices and limits the credibility of experimental results.

Real differences surface under extreme testing conditions. The stability and accuracy of a pressure scanner appear not in a datasheet but inside demanding environments. Windtuner’s 1605S delivers 0.05-class accuracy and remains stable even when test temperatures swing sharply. Some products exhibit temperature-drift errors reaching 0.2% of full scale when ambient temperature rises from 10°C to 40°C, a level that is unacceptable for scientific research. Windtuner pressure scanners run three modes—Run, Calibration, and Purge—and shift between them automatically. Purge mode is especially important in the entire process; it clears dust from pipelines, protects the valve body, and strengthens long-term stability. Many scanners still require factory cleaning or frequent maintenance, raising operating costs and prolonging downtime. Windtuner’s design supports continuous, long-duration experiments without loss of accuracy.

Real applications show how these technical differences translate into value. A university wind tunnel once struggled with timestamp drift of 10–20 ms across multiple sensors, making alignment impossible. After switching to a PTP-based Windtuner pressure scanner, drift dropped to 1–2 ms, meeting research-grade alignment requirements. A small gas turbine manufacturer previously relied on devices that only performed zero calibration, causing poor data stability and repeated test runs. After upgrading to Windtuner pressure scanners with internal multi-point calibration, the team reduced repeat experiments by 30% and recovered significant testing hours. An aviation research institute running long-term compressor tests in high-temperature environments also reported gradual accuracy loss with traditional instruments. Windtuner pressure scanners maintained 0.05-class accuracy throughout, preventing costly re-runs and saving hundreds of thousands of RMB in project expenses.

While 16-channel pressure scanners appear similar at a glance, the underlying technology defines their reliability, application range, and data credibility. Differences between brands are substantial. Windtuner’s Ethernet Intelligent Pressure Scanner elevates domestic scanner technology through advanced sensor-compensation architecture, a complete calibration system, robust valve-body design, and accurate time-synchronization capabilities. For research institutions and industrial test platforms, these advantages make the 1605S not only a tool that collects pressure data, but a system instrument that delivers research-grade measurement for demanding aerodynamic experiments.