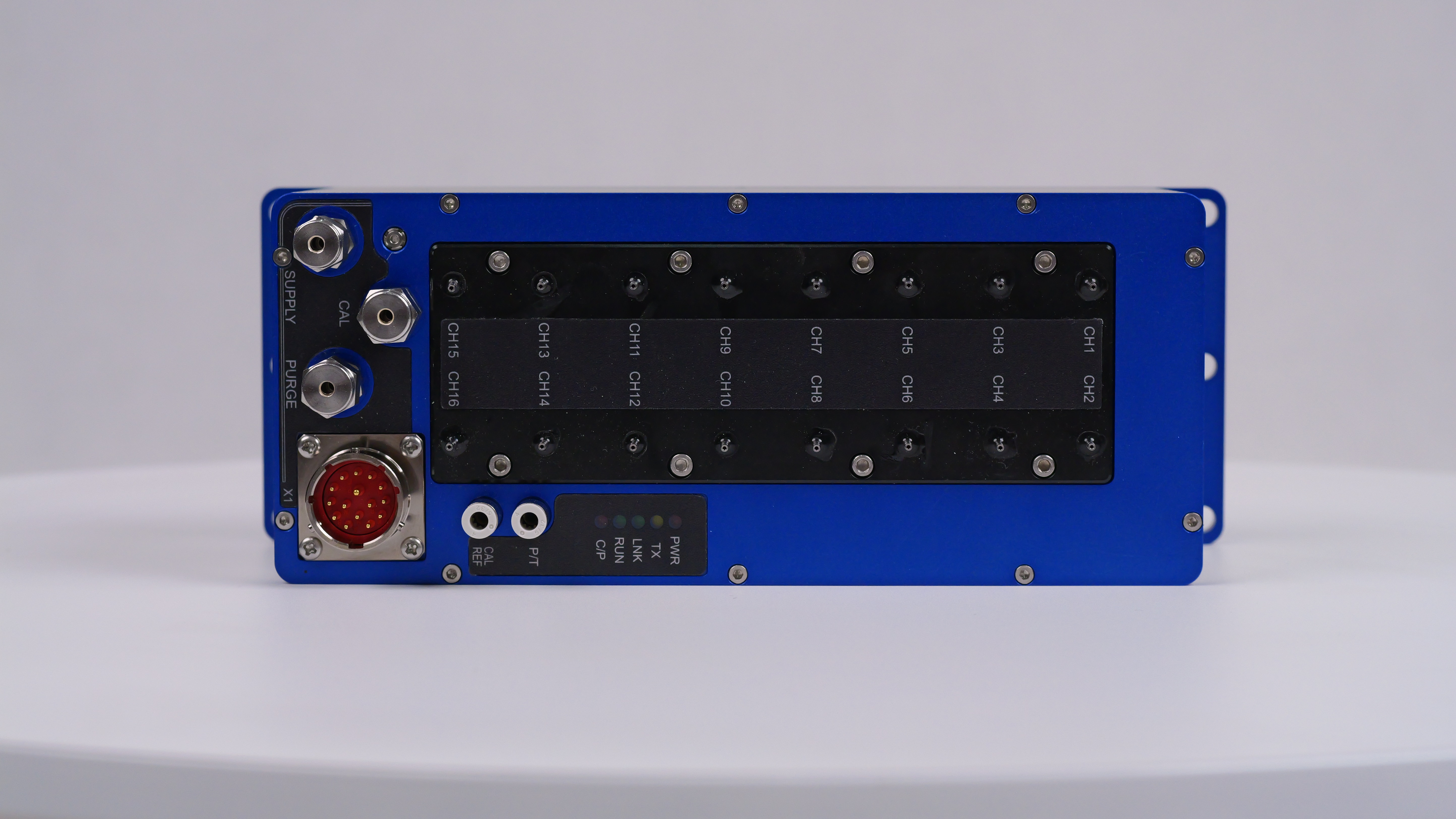

A digital pressure scanner fuses modern electronics, sensor modules, and calibration technologies into a compact measurement instrument with high accuracy, swift transmission, and easy installation. Windtuner pressure scanners follow this concept. Every unit integrates sixteen pressure sensors, paired with an electronic multiplexer and a high-performance A/D converter. The system uses this structure to collect and convert signals for its onboard processor to compute and output into accurate pressure data. Each channel includes a dedicated pressure sensor and a front-end conditioning circuit. Through electronic switching, the scanner achieves multiplexed sampling at a 500 Hz scan rate per channel. High-frequency sampling is essential in commercial aircraft testing, where airflow conditions shift rapidly and demand real-time, accurate feedback.

Windtuner pressure scanners also support multi-point pressure calibration. The system compares all channels against a reference pressure in a single operation, stores the correction coefficients internally, and applies them automatically during acquisition. This calibration capability significantly reduces measurement error, which proves especially valuable when commercial aircraft programs require rigorous accuracy in diverse and complex test environments.

The Windtuner Ethernet Intelligent Pressure Scanner

Applications of Digital Pressure Scanners in Commercial Aircraft Testing

Wind Tunnel Testing

In wind tunnel programs, aircraft models operate under simulated flight conditions that involve highly variable airflow fields. Windtuner pressure scanners perform comprehensive pressure field measurement across as many as sixteen channels, simultaneously recording accurate data at each point. With a 500 Hz scan rate, the scanner reacts quickly to transient or unsteady aerodynamic events and delivers real-time feedback essential for aerodynamic optimization. Engineers rely on this steady stream of digital pressure data to evaluate design decisions with confidence.

Engine Test Stands

Engine test stands demand continuous monitoring of key aerodynamic and combustion parameters across multiple locations in the engine. Windtuner pressure scanners run high-speed acquisition across varied operating conditions and generate accurate, time-aligned pressure readings that support performance analysis, fuel efficiency improvements, and emissions reduction. By delivering clean aerodynamic data from multiple points, the scanners accelerate engine R&D and shorten iteration cycles.

Aerodynamic Performance Evaluation

During aircraft design and development, aerodynamic performance testing determines how the airframe interacts with airflow. Windtuner pressure scanners capture accurate airflow pressure distributions that allow engineers to assess drag, lift, surface pressure characteristics, and structural-flow coupling effects. These insights guide aerodynamic refinement, reduce design uncertainty, and increase overall flight efficiency.

Multi-Channel Synchronous Acquisition and Data Transmission

A defining advantage of digital pressure scanners is synchronized, multi-channel acquisition. Commercial aircraft tests involve complex, time-sensitive measurements, and Windtuner scanners maintain channel-to-channel alignment through software configuration or external triggering. This eliminates the timing discrepancies that often cause analytical errors in engine tests or aerodynamic evaluations.

An onboard processor executes fast data computation and streams the processed digital data over standard networks to client systems. High-efficiency transmission supports large-scale experiments and remote monitoring, making data management and analysis far more streamlined for engineers.

Adaptable for Diverse Test Requirements

Windtuner pressure scanners offer a wide configuration range to support varying pressure levels and application environments, from low-speed wind tunnel tests to high-temperature engine bench conditions. Regardless of the scenario, the scanners maintain accuracy and operational stability, allowing engineers to detect hidden aerodynamic issues early and adjust their testing strategies.

A Core Asset in Modern Commercial Aircraft Testing

As an instrument that integrates advanced electronics and high-accuracy sensor technology, the digital pressure scanner has become indispensable in modern commercial aircraft testing. Through fast response, synchronized multi-channel acquisition, and powerful digital processing, Windtuner pressure scanners deliver decisive value across wind tunnel experiments, engine test rigs, and aerodynamic validation programs.