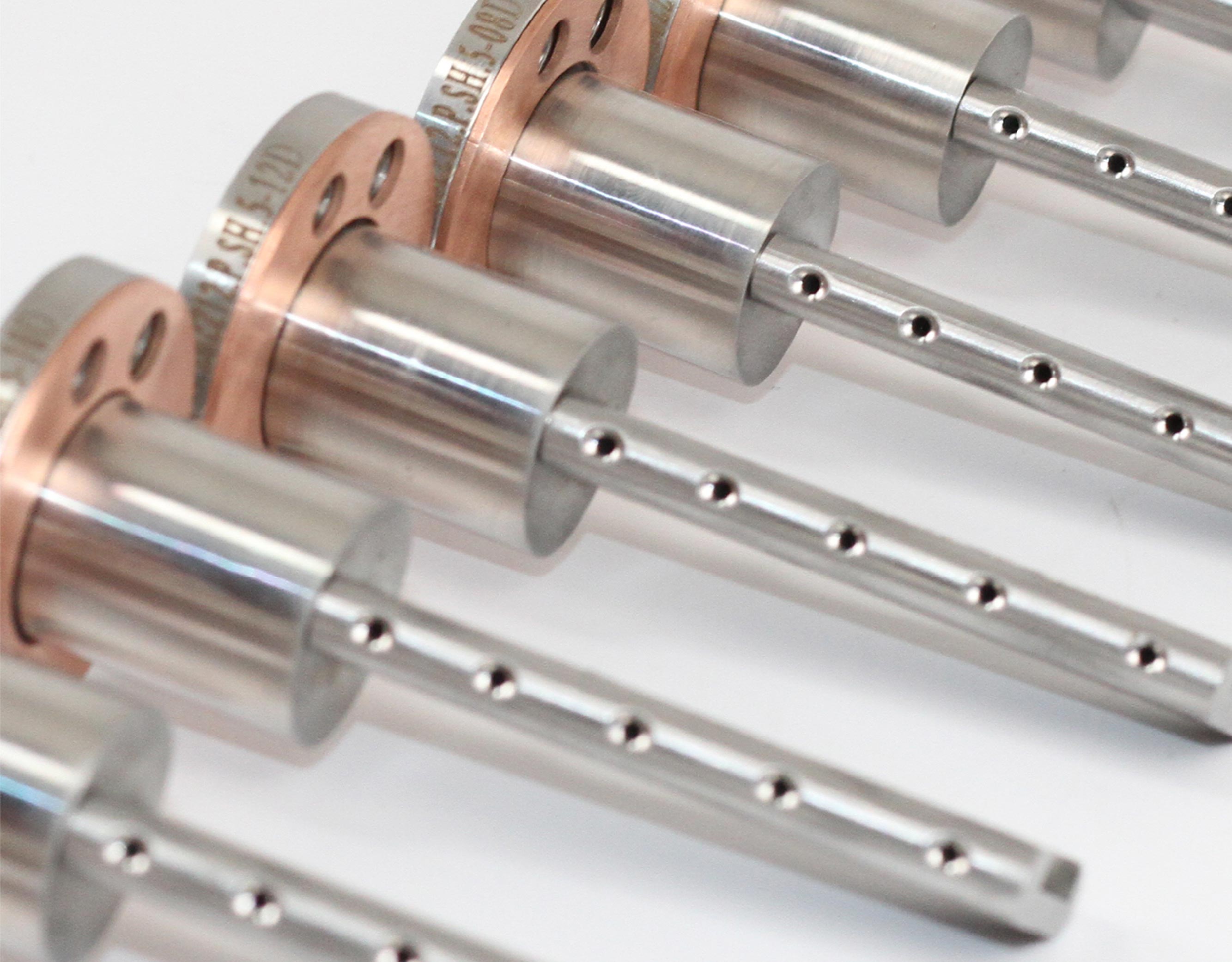

Five-Hole Probes collect three-dimensional information about fluid flow faithfully, even in turbulence, wakes, or vortex-dominated regions. The probe head carries five pressure ports that sense static pressure, dynamic pressure, total pressure, and flow-angle variation simultaneously. Researchers run five-hole probes in wind tunnel experiments, turbomachinery studies, UAV aerodynamic verification, and any project that demands a detailed view of local flow structures.

The pressure scanner acts as the center of the data acquisition system and determines the maximum readings the probe can actually deliver. Pressure signals from multiple ports move through the scanner, which converts those inputs into accurate digital data at high sampling rates. In modern test setups, the scanner must drive performance through accuracy, channel density, and time alignment. Windtuner pressure scanners reach ±0.05%FS accuracy, offer scalable multi-channel acquisition from 8 to 128 channels, and run IEEE1588V2-2008 time synchronization to keep every module on a unified timeline. Those capabilities are critical when a researcher wants clean, consistent measurement results that correlate perfectly with flow visualizations, motion-control systems, or other sensors.

When clients look for a full-stack flow-field measurement solution, they rarely use a five-Hole Probe or a pressure scanner in isolation. These systems often work inside an integrated platform that Windtuner builds for laboratories around the world. A typical setup places the five-Hole Probe inside the test section, routing five pressure signals to the Windtuner pressure scanner through flexible tubing. After the pressure scanner calibrates and samples the signals, data streams through Ethernet to the upper-level measurement and control software interface. The platform incorporates Electric Actuators for probe positioning, total pressure and total temperature acquisition modules for environmental compensation, and a closed-loop control architecture that keeps every part of the experiment synchronized.

Windtuner measurement and control software manages the entire chain with synchronized multi-module sampling, real-time visualization, and rapid analysis, turning a complex fluid experiment into a controllable process rather than a manual, error-prone task. When the pressure scanner and the five-Hole Probe operate as a single system, the advantages extend far beyond hardware integration. The pairing delivers multidimensional data fusion, with the probe recovering flow direction and velocity distribution while the scanner drives high-accuracy, high-density pressure acquisition. Together, they create the foundation for reconstructing a full three-dimensional flow field.

Time consistency is another major benefit. Windtuner pressure scanners run IEEE1588V2 time synchronization to align every data source—probes, Electric Actuators, motion controllers, and environmental sensors—to the same time axis. This drives reliable correlation between measurement data and motion states, which is essential for CFD comparison, compressor cascade research, rotating machinery studies, and dynamic flow diagnostics.

The modular architecture supports large-scale expansion. Multiple pressure scanners can operate in parallel with probe arrays to support full-field testing in large wind tunnels or complex turbomachinery rigs. As the testing scale grows, the system maintains accuracy and timing consistency without sacrificing sampling performance.

Windtuner has developed deep capabilities in both pressure scanners and multi-hole probe engineering. As one of the earliest companies in China dedicated to system-level flow-field measurement and control solutions, Windtuner builds its platforms on R&D for probes, scanners, calibration wind tunnels, and measurement and control software. Windtuner operates a Wind Tunnel Laboratory accredited by CNAS and offers joint calibration for probes and pressure scanners, delivering laboratory-grade accuracy that strengthens confidence for clients across aerospace, universities, automotive wind tunnels, and international partners. These strengths have helped Windtuner pressure scanners earn recognition from clients worldwide and gradually build relationships throughout the European and American markets.

When a pressure scanner meets a five-hole probe, we get more than the sum of these components. The partnership forms an intelligent measurement chain that drives aerodynamic research with accuracy, efficiency, and scalability. This system-level approach is positioning Windtuner as a rising force in global flow-field measurement and control, bringing reliable, high-performance, fully integrated solutions to laboratories and test facilities pursuing the next breakthroughs in fluid dynamics.