In complex measurement and control environments such as wind tunnel testing, engine test benches, and flight experiments, the pressure scanner serves as the core hardware for multi-point pressure acquisition. Its compatibility with analysis software and testing systems directly determines the efficiency and reliability of the entire testing framework.

Windtuner has been advancing R&D around open interfaces, modular hardware, and an integrated domestic software-hardware ecosystem. This effort has significantly enhanced the adaptability and engineering efficiency of Windtuner pressure scanners in system integration.

A key strength lies in the open design supporting multiple protocols and interfaces. Windtuner Ethernet Intelligent Pressure Scanners connect seamlessly with mainstream data acquisition platforms and real-time controllers through standard Ethernet protocols such as TCP/IP and UDP, minimizing latency and instability from protocol conversion. This open structure enables direct integration across various software environments, supporting synchronized sampling and unified clock management in large-scale experimental setups.

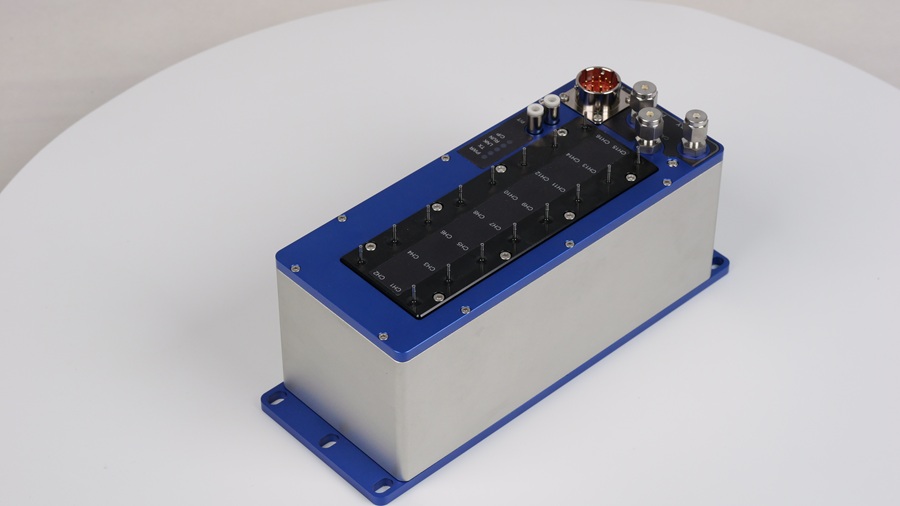

The modular hardware architecture adds remarkable flexibility for system integration. With scalable channel configurations ranging from 16 channels per unit to higher counts through modular expansion, clients can easily extend the system according to model configurations or measurement point distribution. This approach prevents over-investment in large initial setups and simplifies maintenance and on-site replacements. Integrated atmospheric pressure and temperature sensors further streamline coupling with environmental measurement systems.

Windtuner pressure scanners fully support the IEEE 1588V2-2008 Precision Time Protocol (PTP), achieving sub-microsecond synchronization among distributed data acquisition modules. In multi-module or multi-node setups, such as wind tunnel sections or onboard data systems, all channels share a unified time base—making true multi-point synchronized measurement possible. PTP eliminates sampling delays between devices, ensuring pressure, temperature, and angular data are precisely aligned. This synchronization provides reliable input for flow field reconstruction and unsteady aerodynamic analysis.

For aerodynamic testing applications involving rapid flow changes—such as gas turbines, high-speed trains, and UAVs—data acquisition systems face extreme demands in sampling rate and response time. Windtuner has optimized its electronic signal path and data processing algorithms, achieving high-bandwidth sampling capable of accurately capturing transient pressure fluctuations. When combined with IEEE 1588 synchronization, the system enables high-fidelity, time-aligned transient data across modules—ideal for studying unsteady flow phenomena.

Historically, domestic research institutions have relied on imported high-precision pressure scanners, leading to extended integration cycles and costly maintenance. Windtuner has broken this dependency through fully self-developed hardware combined with a software platform that ensures safe, controllable, and high-performance alternatives for aerospace, energy, and automotive research.

Windtuner also maintains a robust local technical support network offering on-site commissioning, remote diagnostics, and rapid maintenance services—allowing research teams to operate with greater confidence and efficiency.

With its open system interfaces, modular architecture, IEEE 1588V2 precision time synchronization, and comprehensive localized support, Windtuner provides a highly compatible, efficient, and reliable solution for advanced aerodynamic testing. This breakthrough in compatibility enables domestic pressure scanners to integrate seamlessly with international systems—offering superior cost-performance and greater technological independence, driving innovation and accelerating research in wind tunnel testing, flight trials, and energy equipment evaluation.