1.Zero-point calibration function

Zero-point calibration is a necessary pre-test operation, aiming to ensure that the reference state of the equipment at the beginning of the measurement is accurate and error-free, thereby guaranteeing the precision of data collection throughout the entire testing process. Zero calibration is performed before use to ensure the accuracy of each test. This helps to avoid test result deviations caused by small errors. The frequency of zero-point calibration depends on factors such as the type of equipment, the usage environment, and measurement requirements. Generally speaking, it is recommended to perform zero-point calibration before each test begins, after the equipment has not been used for a long time, after significant changes in environmental conditions, or when abnormal measurement data is detected. For applications with extremely high precision requirements, zero-point calibration may be necessary once a day or even once a test cycle.2. Full-scale calibration function

It can determine whether the output signal of the Ethernet Intelligent Pressure Scanners at the maximum working pressure (full-scale pressure) is consistent with the expected value. Through calibration, nonlinear errors, sensitivity drift, hysteresis effects and other phenomena of the sensor under high pressure conditions can be discovered and corrected, ensuring the consistency between the measured values and the actual pressure values throughout the full measurement range. This helps to provide accurate pressure data, which is crucial for applications such as flow field analysis, performance evaluation, and fault diagnosis.Full-scale calibration ensures the measurement accuracy of the Ethernet Intelligent Pressure Scanners under the highest pressure conditions, enhances the credibility of the collected data, and makes decisions such as fluid mechanics analysis, structural strength calculation, and process parameter adjustment based on these data more scientific and reasonable.

For projects that require long-term monitoring or repeated testing, the full-scale calibration of the Ethernet Intelligent Pressure Scanners helps ensure the comparability of measurement results between different times and different devices. The calibrated equipment generates more consistent data under the same pressure conditions, which is conducive to time series analysis, cross-validation among devices, or reproducibility verification of experimental results.

3. Full-scale calibration function

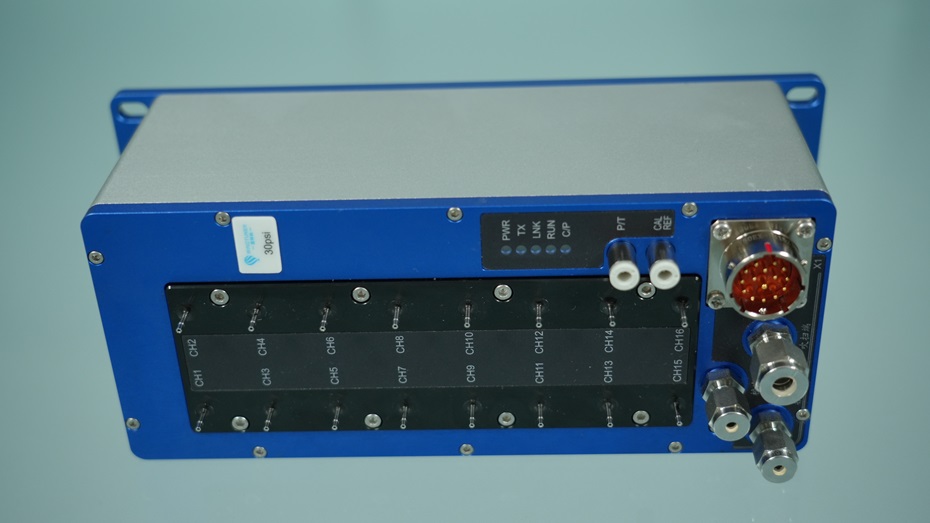

The Windtuner Ethernet Intelligent Pressure Scanners is equipped with 16 high-precision pressure sensing modules. This multi-channel architecture enables the device to simultaneously connect multiple pressure modules, corresponding to multiple pressure measurement points in the flow field to be measured. It greatly enhances the coverage and data density of pressure measurement, which is crucial for understanding the three-dimensional pressure distribution of complex flow fields, especially in situations involving the surface pressure distribution of aircraft, wind tunnel experiments, and pressure monitoring of pipeline networks that require high-resolution spatial sampling.Each pressure acquisition channel is equipped with a high-precision pressure sensor, which can accurately sense and convert the measured pressure into an electrical signal. These sensors typically feature low drift, high linearity and wide dynamic range, ensuring the accuracy and consistency of the measurement results. In addition, the WindtunerEthernet Intelligent Pressure Scanners also supports the customization of inter-channel measurement range and accuracy to adapt to measurement tasks with different pressure ranges and accuracy requirements.

4. Purging function

By introducing clean gas into the pressure sensor and its connected pipelines, a continuous or periodic airflow is formed to remove dust, moisture, oil mist and other contaminants adhering to the surface of the sensor, the interior of the pipeline and the connected components. It helps to reduce the sources of measurement errors and avoid measurement signal distortion or sensor blockage caused by the accumulation of contaminants.Through the effective purging function, the Windtuner Ethernet Intelligent Pressure Scanners can significantly reduce the sensor failure rate caused by pollution and extend the service life of the equipment. More importantly, maintaining the cleanliness of sensors and measurement channels continuously can ensure the reliability of measurement data and prevent pressure reading deviations caused by contaminants. This is crucial for industrial processes that rely on precise pressure data for decision-making or control.

In summary, the four core functions of the WindtunerEthernet Intelligent Pressure Scanners are powerful, facilitating intelligent control and convenient operation. It has established the competitive advantage of WindtunerEthernet Intelligent Pressure Scanners in the field of flow field measurement and control, making it an ideal choice for flow field research and engineering applications.