1. Why is the measurement accuracy of Ethernet Intelligent Pressure Scanners important?

1.1 Affect the authenticity of flow field modeling

In complex flow fields such as airplane wing surface turbine blade passage or wind tunnel test area small pressure changes often contain key information such as flow separation boundary layer state shock wave location and so on. If the measurement error of Ethernet Intelligent Pressure Scanners is large, the reconstruction of the flow field will be distorted, which will affect the judgment of the overall aerodynamic performance.

1.2 Determine the accuracy of product optimization direction

During the product design phase, engineers rely on accurate pressure data for structural optimization, material selection, and energy consumption control. For example, in the design of new energy vehicles, by accurately measuring the pressure distribution around the vehicle, the drag coefficient can be effective and the battery life can be improved. If the measurement accuracy is insufficient, it may lead to wrong design decisions, but the cost and even potential safety hazards.

1.3 Related to system security and stability

In high-temperature and high-pressure systems such as engines and gas turbines, local pressure abnormalities may be early fault signals. High-precision Ethernet Intelligent Pressure Scanners can capture these subtle changes within millisecond response time, providing a reliable basis for early warning systems to avoid major accidents.

1.4 The data base that underpins scientific research

For universities and research institutes, the accuracy and reproducibility of experimental data are the basis for the credibility of scientific research results. The pressure measurement error conference directly affects the scientificity and authority of the conclusions of the paper. Therefore, high-precision Ethernet Intelligent Pressure Scanners is the guarantee of high scientific research work.

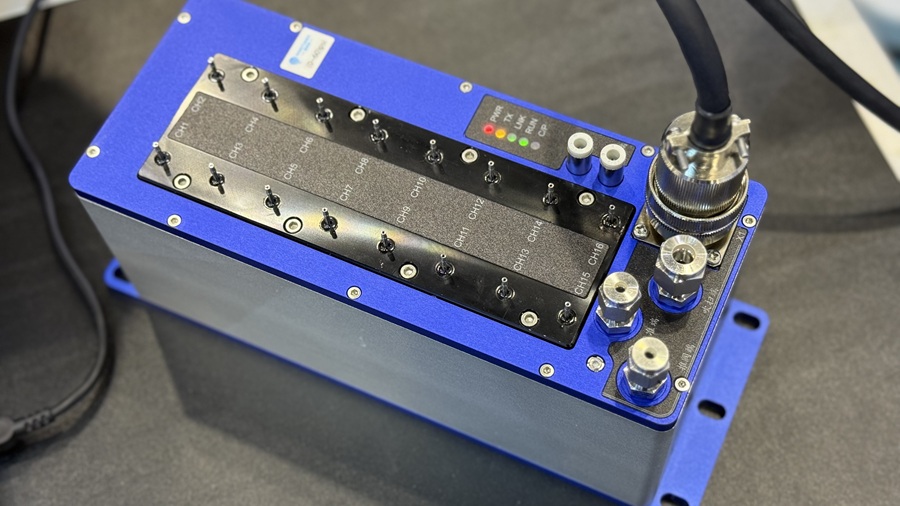

2. Windtuner Ethernet Intelligent Pressure Scanners: ± 0.05 FS accuracy, benchmarking against the international advanced level

In recent years, with the rapid development of domestic sensor technology and intelligent systems, domestic enterprises have made significant breakthroughs in the field of high-end instrumentation. Among them, the Ethernet Intelligent Pressure Scanners series products launched by Windtuner Intelligent Technology Co., Ltd. have achieved a measurement accuracy of ± 0.05% FS (full range). This indicator has not only reached the technical level of international mainstream brands, but also in some application scenarios. show unique advantages.

Technical analysis: How to achieve high precision of ± 0.05 FS?

Highly sensitive silicon pressure sensor: The silicon piezoresistive chip has higher sensitivity, can capture micropa-level pressure fluctuations, and can achieve ± 0.05% FS accuracy in a wide temperature range of-40 °C to 125 °C. It supports multi-channel high-density array integration, and has anti-electromagnetic interference and durability of millions of pressure cycles, and other precision measurement and control requirements.

Intelligent compensation algorithm: Through built-in temperature compensation, nonlinear correction and dynamic filtering algorithm, it can effectively eliminate interference and ensure consistent measurement performance under different working conditions.

Multi-channel synchronous acquisition architecture: supports simultaneous acquisition of multiple measurement points, and has a high degree of consistency between channels to avoid system errors caused by channel differences.

Modular and standardized design: Easy for quick replacement, maintenance and expansion, suitable for various scenarios such as laboratory and field testing.