Stability testing is of extremely significant importance for the WindtunerEthernet Intelligent Pressure Scanners, mainly reflected in the following aspects:

1. Ensure measurement accuracy and reliability

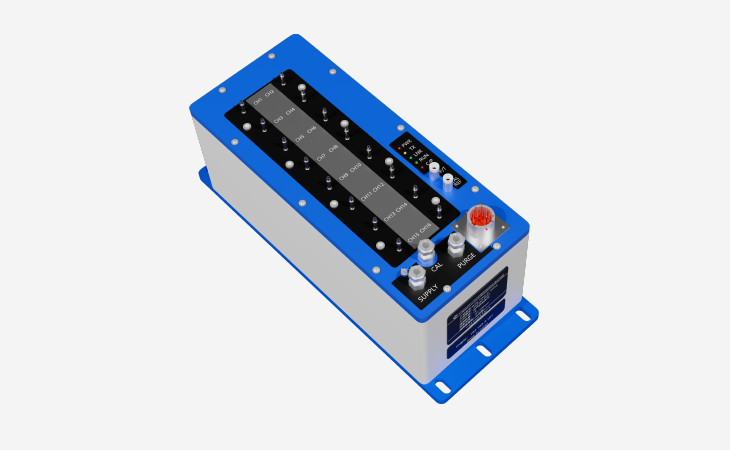

The Ethernet Intelligent Pressure Scanners, as a key flow field measurement and control device, its core function lies in accurately and rapidly measuring multi-point pressure data. Stability testing can verify whether the Ethernet Intelligent Pressure Scanners can maintain stable measurement performance under various working conditions (such as different temperatures, humidity, pressure ranges, long-term operation, etc.), and ensure the accuracy and consistency of the output data. Only the Ethernet Intelligent Pressure Scanners that has undergone strict stability tests can provide users with reliable pressure data in practical applications, thereby supporting precise flow field analysis and engineering decisions.

2. Meet the requirements of industry standards and norms

Many industries (such as aerospace, automotive manufacturing, energy and chemical engineering, etc.) have strict performance standards and certification requirements for pressure measurement equipment. Stability testing is an important link to meet these standards and obtain relevant certifications. For example, the Ethernet Intelligent Pressure Scanners may need to comply with international standards such as ISO, ASME, EN, or specific specifications of specific industries, and these standards usually contain strict regulations on the stability of the equipment. Through the stability test, Windtuner can prove that its Ethernet Intelligent Pressure Scanners complies with these standards, thereby enhancing the market competitiveness and user trust of the product.

3. Enhance product competitiveness and brand image

Windtuner Technology is committed to breaking the long-term monopoly of foreign products in the field of flow field measurement and control. Its Ethernet Intelligent Pressure Scanners, as the flagship product, must have stability comparable to the international advanced level in order to truly achieve domestic substitution. Through rigorous stability tests, Windtuner can prove the outstanding performance of its products under long-term use and extreme conditions, which is no less than that of foreign competitors, and even surpasses them in some aspects. Such test results are conducive to enhancing the market competitiveness of WindtunerEthernet Intelligent Pressure Scanners, establishing the high-end brand image of "Made in China", and attracting more domestic and even international customers.

4. Prevent potential malfunctions and extend service life

Stability testing can reveal potential problems of the Ethernet Intelligent Pressure Scanners during long-term operation or under extreme conditions, such as sensor drift and aging of electronic components. By detecting and solving these problems early, Windtuner can optimize product design, improve production processes, and enhance the durability and service life of Ethernet Intelligent Pressure Scannerss. This not only reduces the maintenance costs for users, but also helps to minimize measurement interruptions or data distortions caused by equipment malfunctions, ensuring the smooth progress of users' experiments or production activities.

5. Support continuous improvement and technological innovation

The data collected through stability testing is not only the basis for evaluating the current product performance, but also the key input driving the product's iterative upgrade. Through in-depth analysis of the test results, Windtuner can identify the factors affecting the stability of the product, carry out targeted technological research and development and innovation, and continuously improve the performance boundaries of the Ethernet Intelligent Pressure Scanners. This continuous improvement process based on empirical data is crucial for Windtuner to maintain its technological leadership and respond to future changes in market demand.

In conclusion, stability testing is a necessary means for Windtuner Ethernet Intelligent Pressure Scanners to ensure product quality, enhance market competitiveness, prevent faults, extend service life and promote technological innovation. It is an indispensable part of its product research and development and quality management.